Spare Parts for QIDI Q2

No se pudo cargar la disponibilidad para recoger

Utilice este texto para fomentar la comunicación o promover el intercambio en las redes sociales.

Q2 Hotend Cooling Fan

The Hotend Cooling Fan cools the hotend to avoid premature filament softening and clogs.

Q2 Model Cooling Fan

The Part Cooling Fan, located at the toolhead's base, works in tandem with the Air Duct to swiftly cool extruded filament.

Q2 Auxiliary Fan

The Q2 Auxiliary Fan is a 4-Pin PWM Fan with RPM Feedback installed on the left side of the chamber, providing better cooling conditions for high-speed printing.

Q2 Camera

The camera is a low frame rate camera that enables remote live broadcast and time-lapse shooting.

Working Temperature: -20°C to 70°C

Resolution Ratio: 1920*1080

Maximum Image Transfer Rate: 1-30fps

EFL: 2.3mm

FOV: 130°±15°

F/No: 2.0

Q2 Extruder

The Q2 extruder features hardened steel double gears to increase extrusion force and prevent slipping.

Q2 Filament Runout Sensor

This sensor is used in the Extruder to detect the presence of the filament, and also detect the Filament Cutter lever.

Q2 Bimetal hotend

It is recommended to use only one type of filament in a single nozzle. Switching between multiple filaments in one nozzle may cause nozzle blockage.

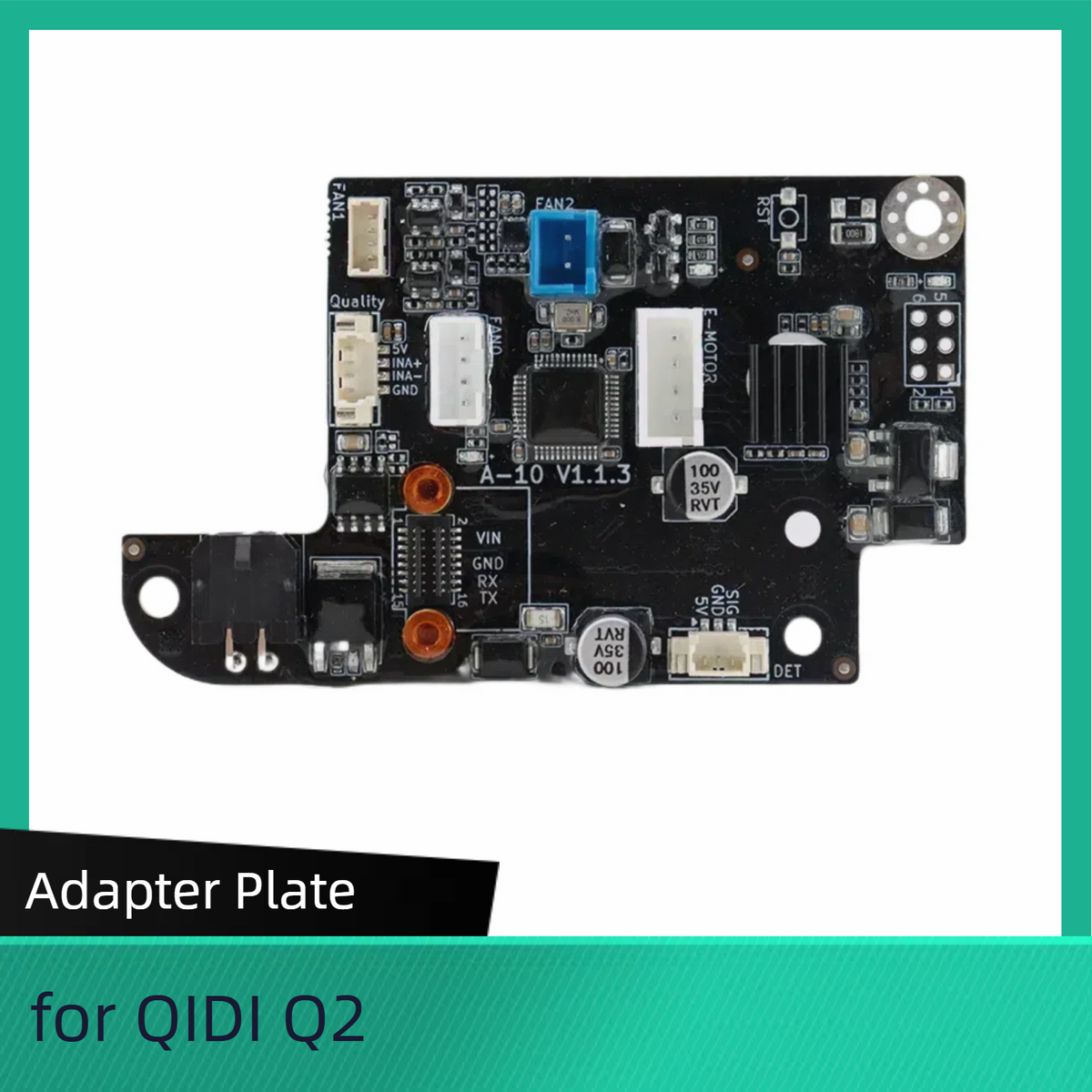

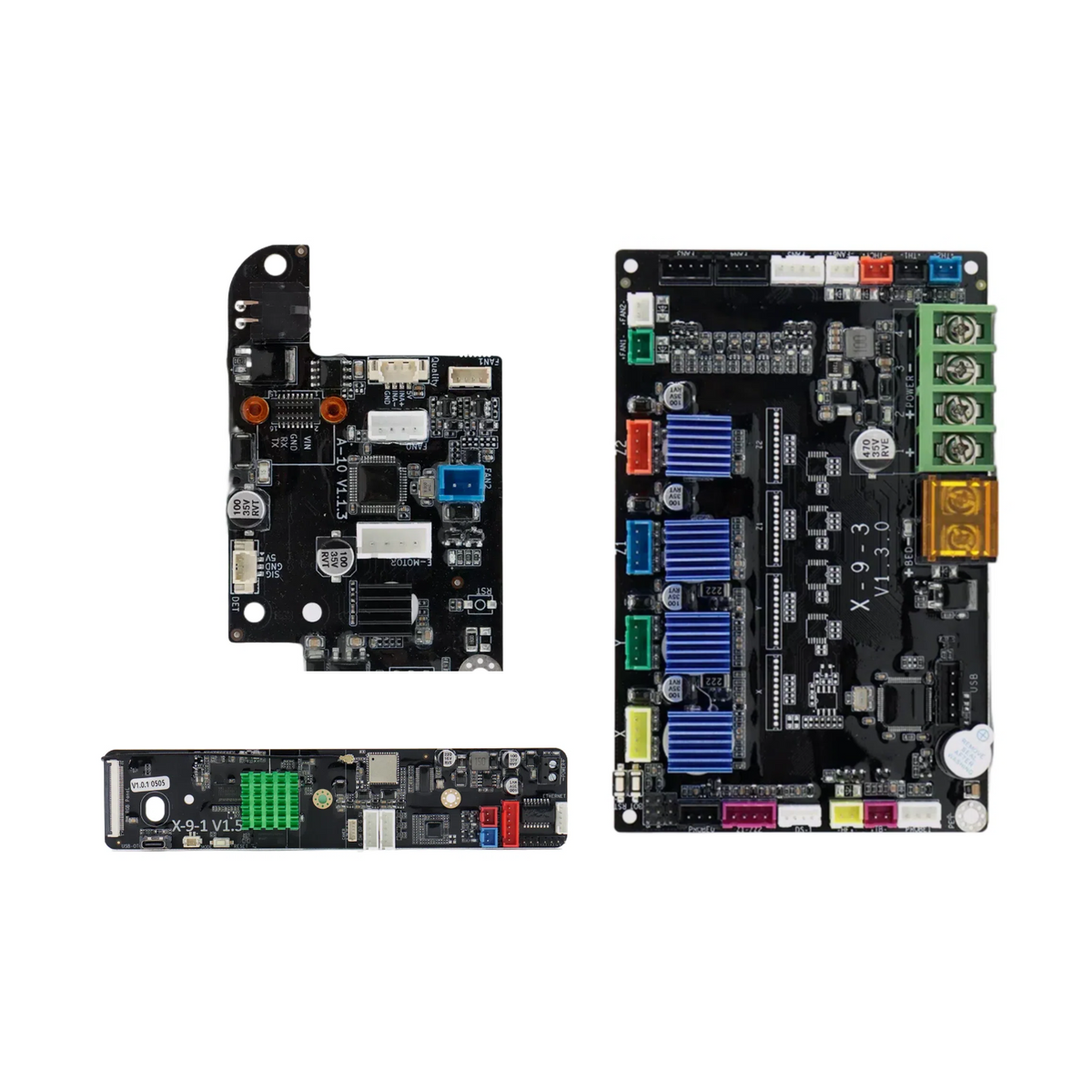

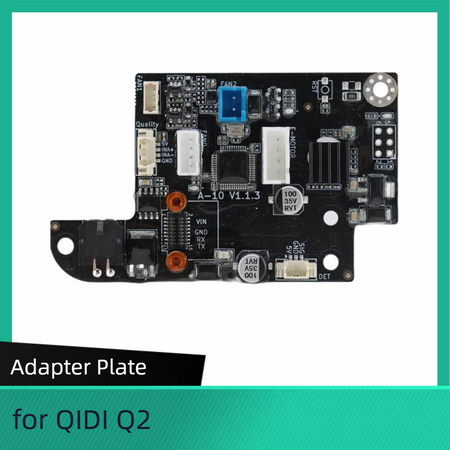

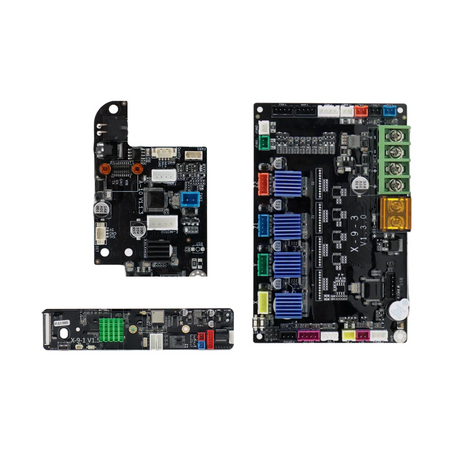

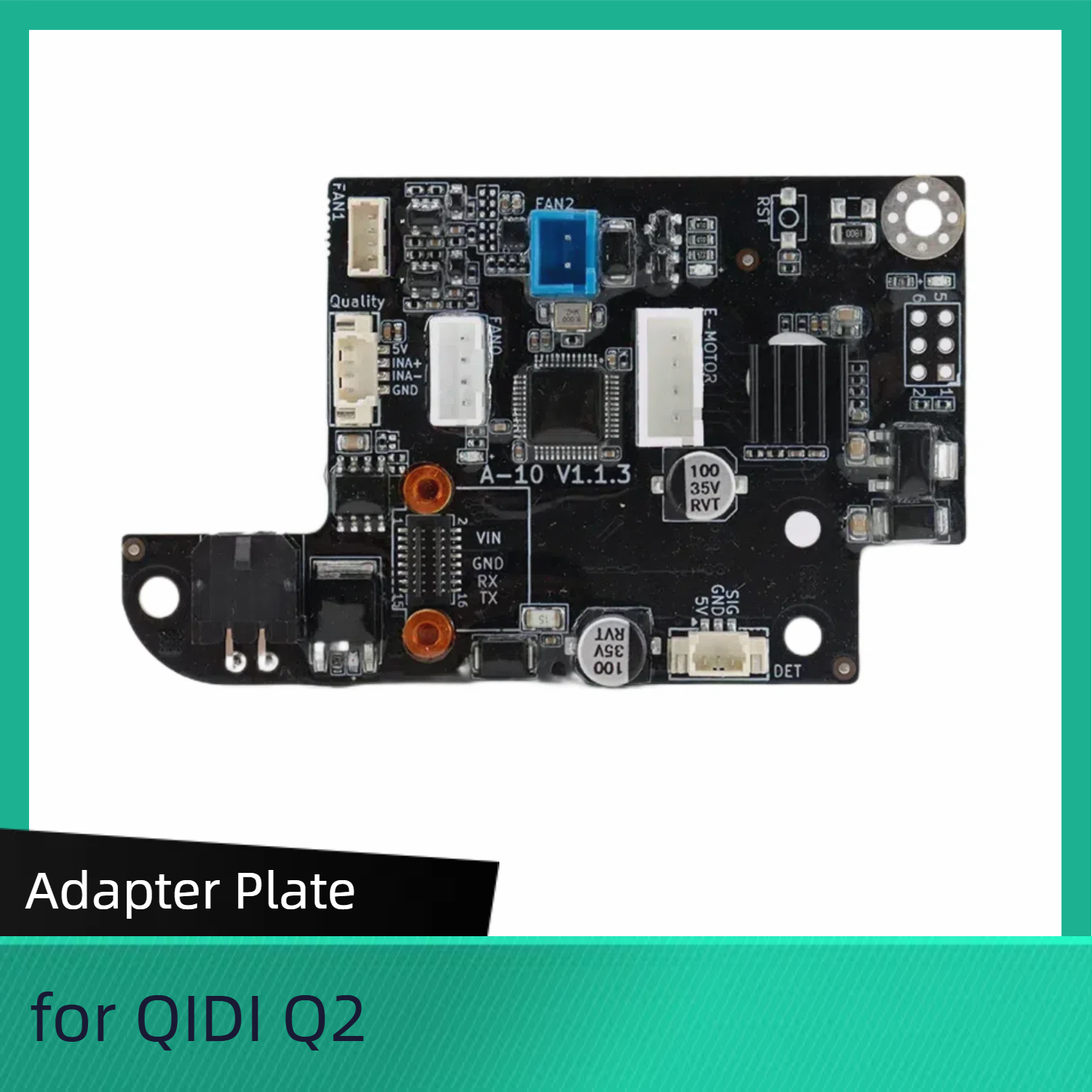

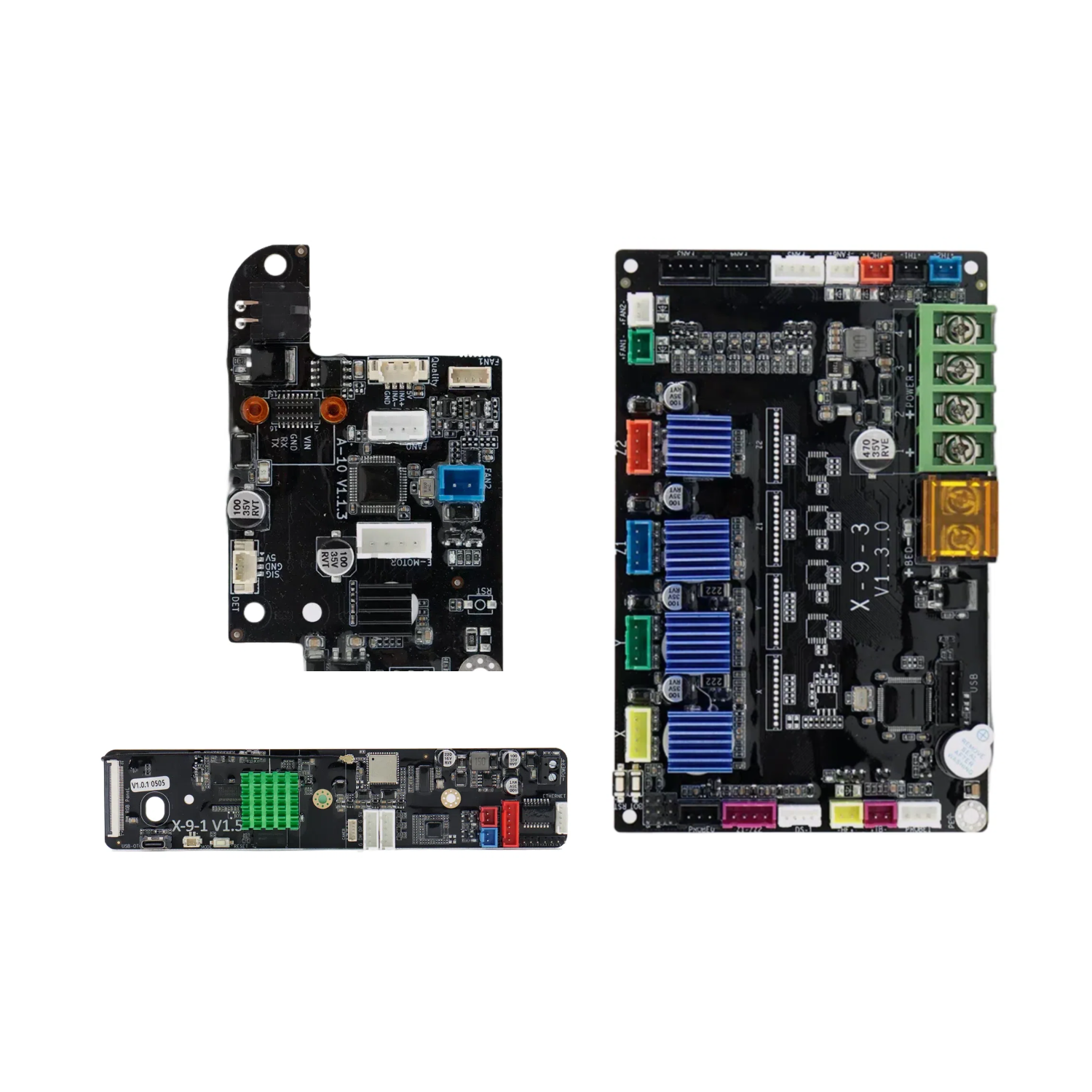

Q2 Adapter Plate

Optimize electrical connections, improve stability and scalability

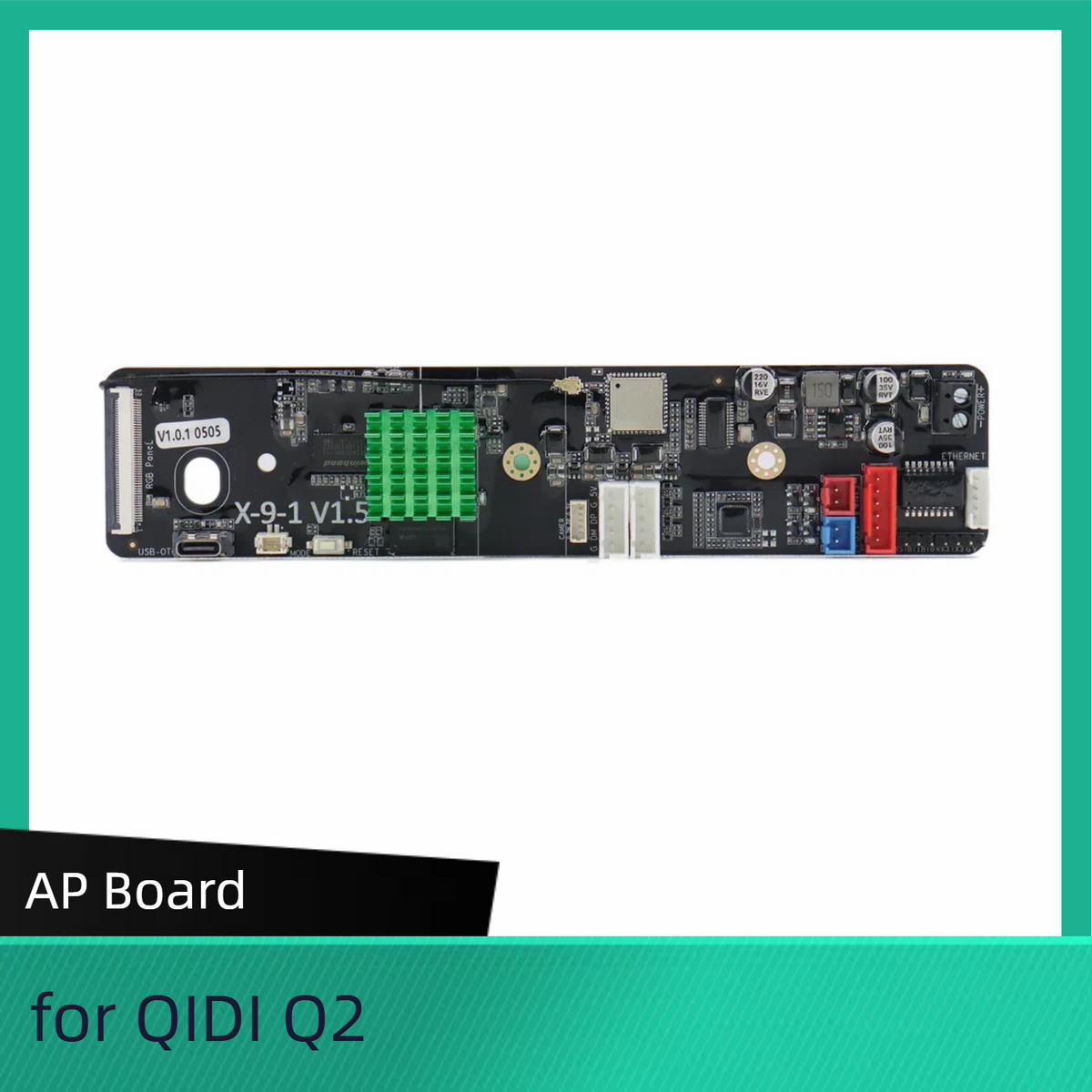

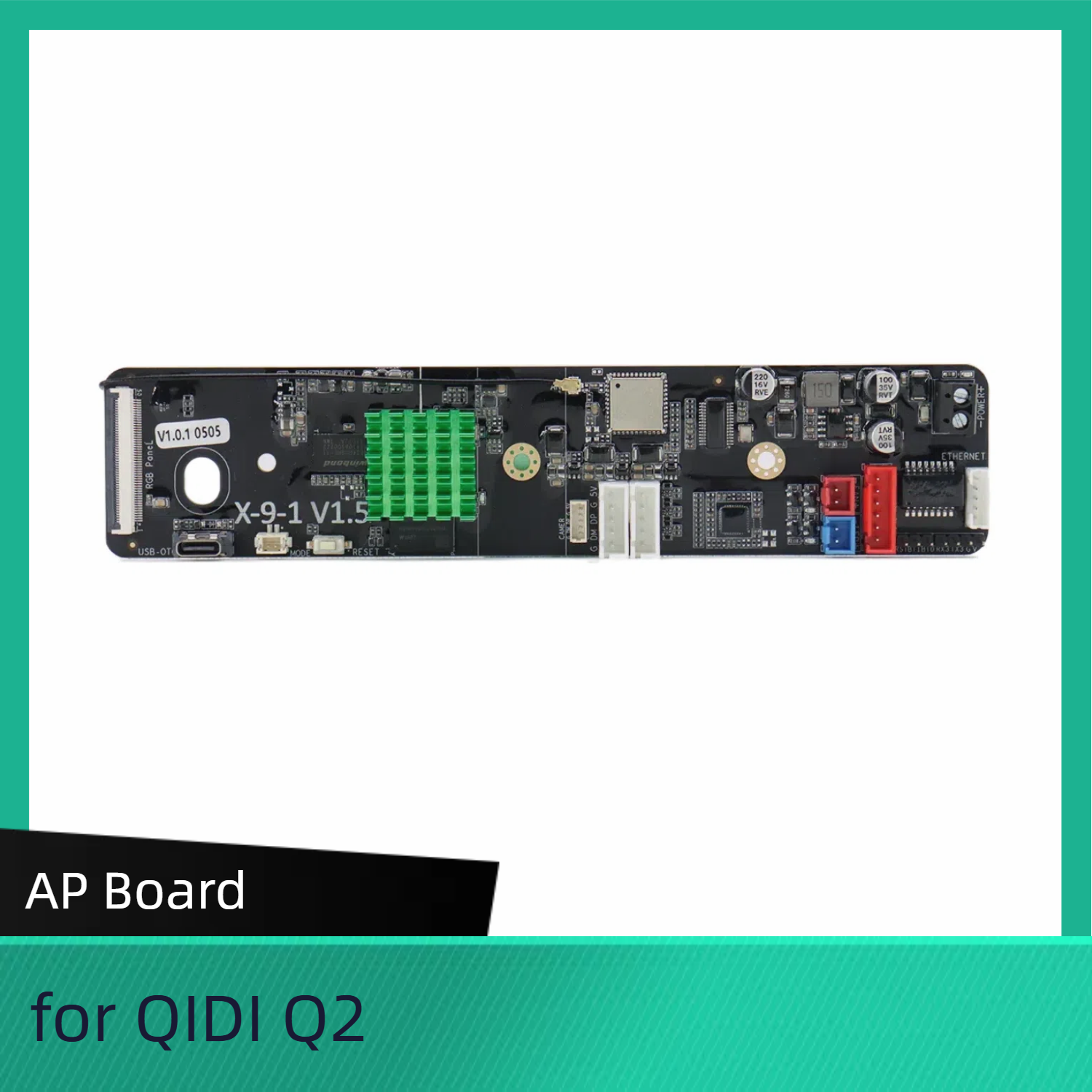

Q2 AP Board

High-performance control - handles complex motion algorithms (such as high-speed printing, closed-loop control) to improve printing accuracy and speed.

Multi-tasking - manages printing, temperature control, network communication, camera monitoring and other tasks at the same time.

Intelligent expansion - supports advanced functions such as Wi-Fi/cloud control, multi-sensors, AI detection, etc.

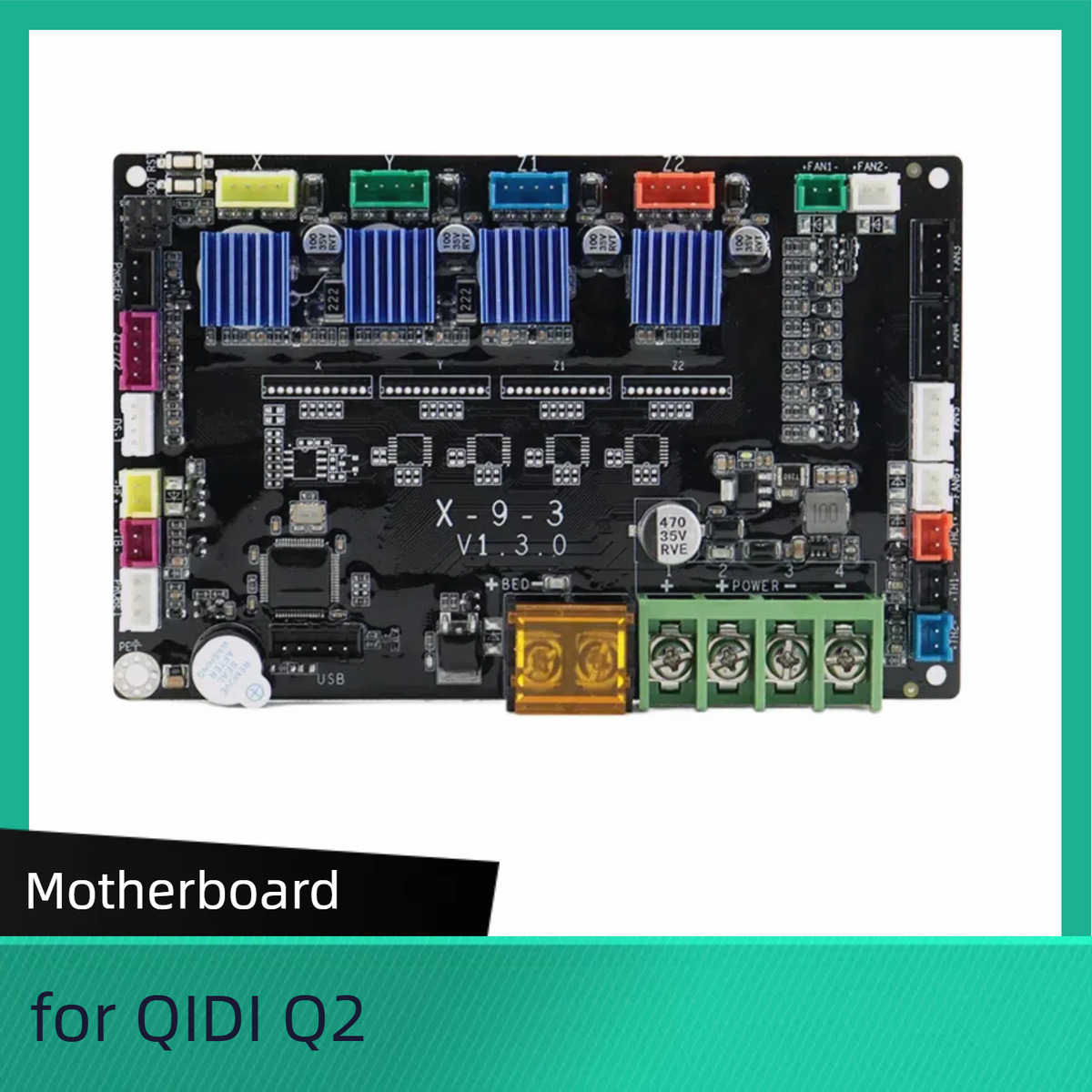

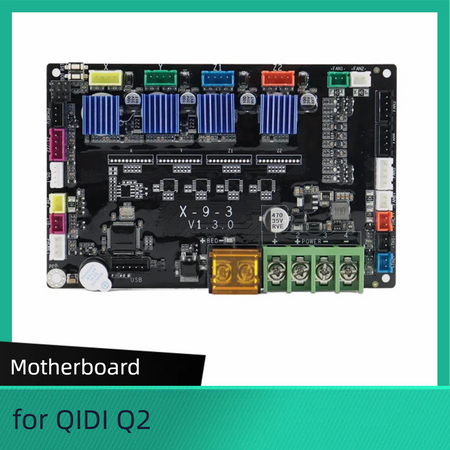

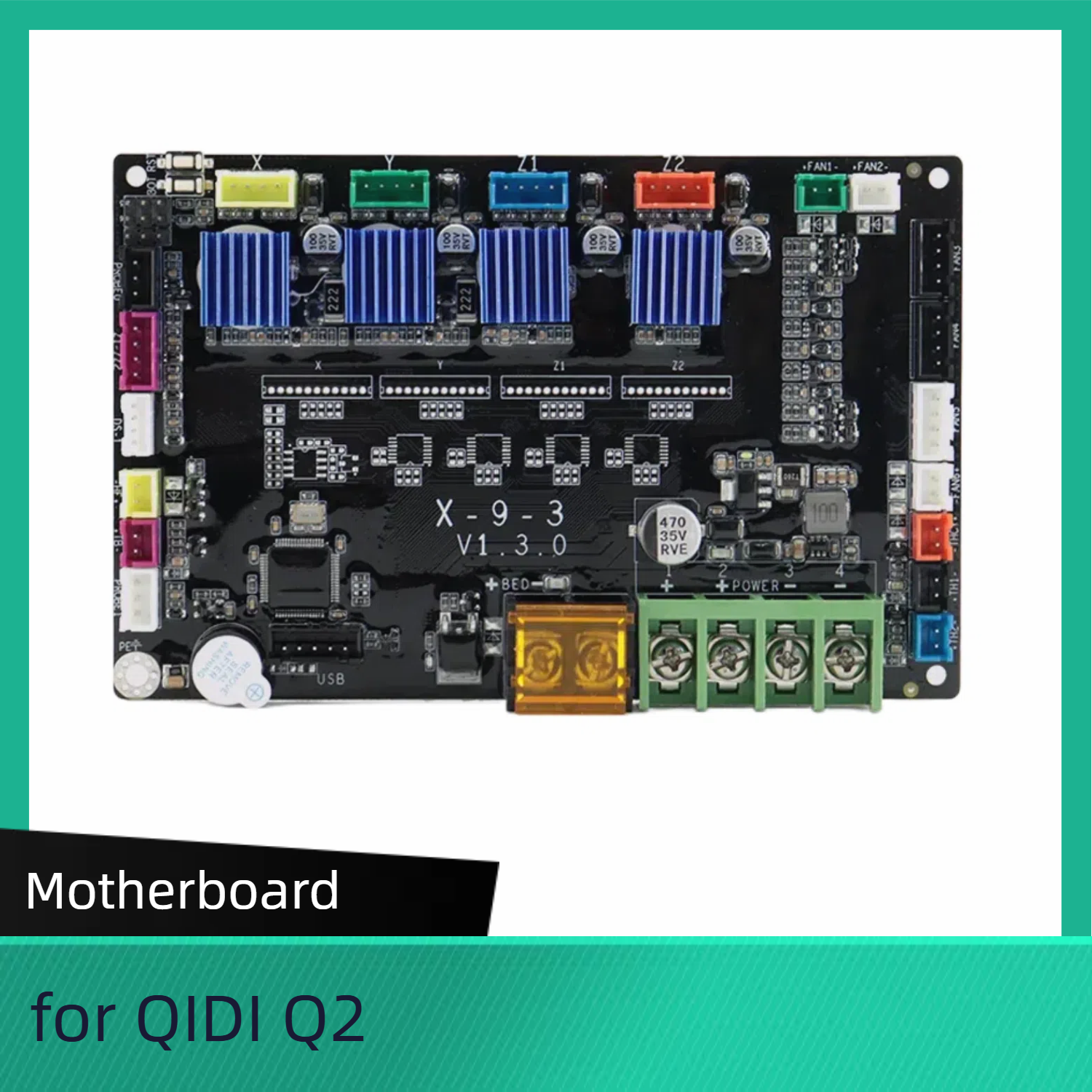

Q2 Motherboard

The motherboard is responsible for coordinating the work of all hardware components to ensure the precise execution of the printing process.

Q2 Dual-Sided PEI Plate

1. Double-sided design for durability

2. Strong magnetic base for stability and convenience

3. Imported high-quality PEI material with excellent PEI coating performance, hot-attach and cold-detach

4. Easy to clean with anhydrous alcohol wipe

5. Surface temperature resistance:up to 120℃

6. Overall dimensions: 280 x 280 mm

Precautions:

Dust and grease accumulation on the build plate will reduce adhesion. Regular cleaning of the build plate surface with detergent and water is recommended to maintain optimal adhesion.

Increasing the hot bed temperature can enhance adhesion. Users should adjust the hot bed temperature according to their specific needs to achieve optimal adhesion.

Before removing a printed model, always wait a few minutes for the build plate to cool, allowing for easy removal. This prevents damage to the build plate and ensures a long product life.

This item is a consumable part and will degrade over time.

Dual-Sided Smooth Plate

Smooth and Matte Surface Finish

Compared with ordinary PEI board, it provides a smoother printing texture and a smooth surface for your prints.

Q2 Hotend Silicone Sock

The Silicone Sock for Hotend is made from high-quality silicone for higher temperature resistance (rated to 300°C printing temperatures).

Ensuring optimal thermal insulation and tear resistance, the silicone sock also provides the nozzle with long-lasting protection from cooling air and plastic adhesion.

Q2 Cutter Blade

Q2 Cutter Blade

Q2 Cutter Blade is used to cut the filament when replacing the filament or switching between multiple colors.

Q2 Wiper Silicone Case

The Wiper Silicone Case is used to clean the hot nozzle before starting a print job. ![]()