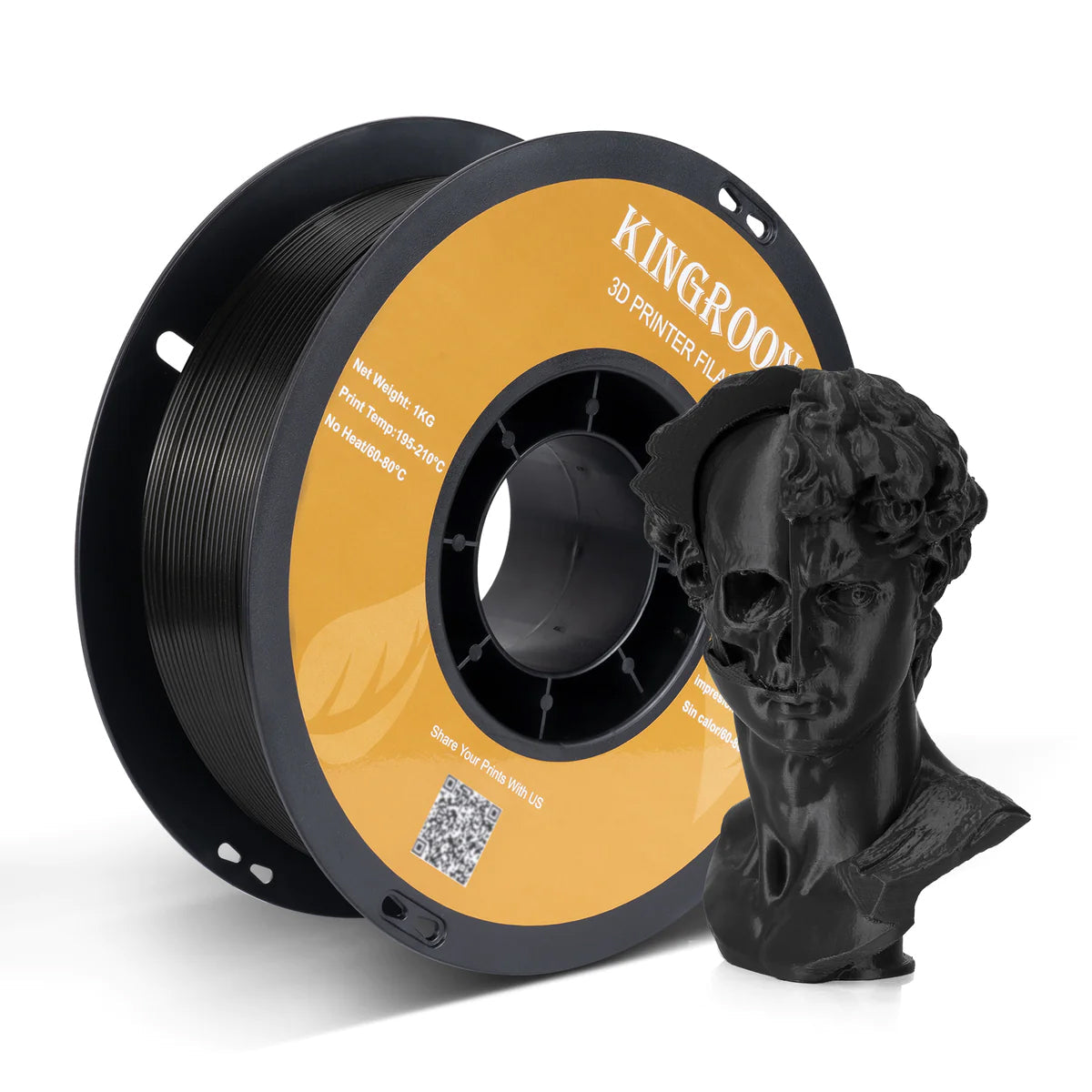

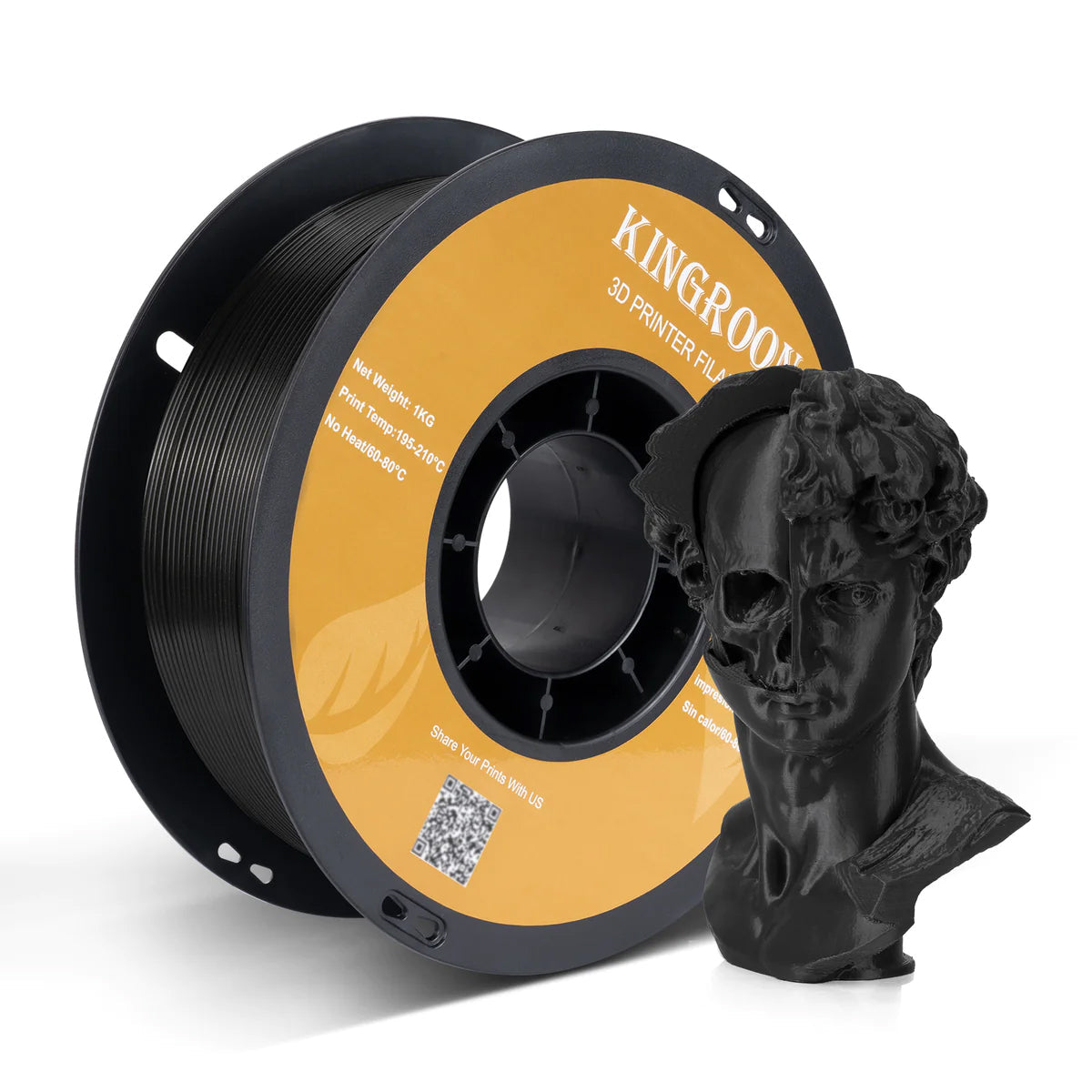

Filamento 3D de nailon de fibra de carbono PA+CF, 1 KG

No se pudo cargar la disponibilidad para recoger

Utilice este texto para fomentar la comunicación o promover el intercambio en las redes sociales.

Filamento 3D de nailon de fibra de carbono PA+CF, 1 KG

El filamento 3D de nailon de fibra de carbono PA+CF está fabricado con un copolímero de nailon especial y fibra de carbono de alto módulo. Este es el material ideal para aplicaciones industriales que requieren propiedades de resistencia térmica, mecánica y química superiores y al mismo tiempo conservan la facilidad de impresión que usted espera.

El paquete incluye

1 rollo de relleno, 1KG por rollo.

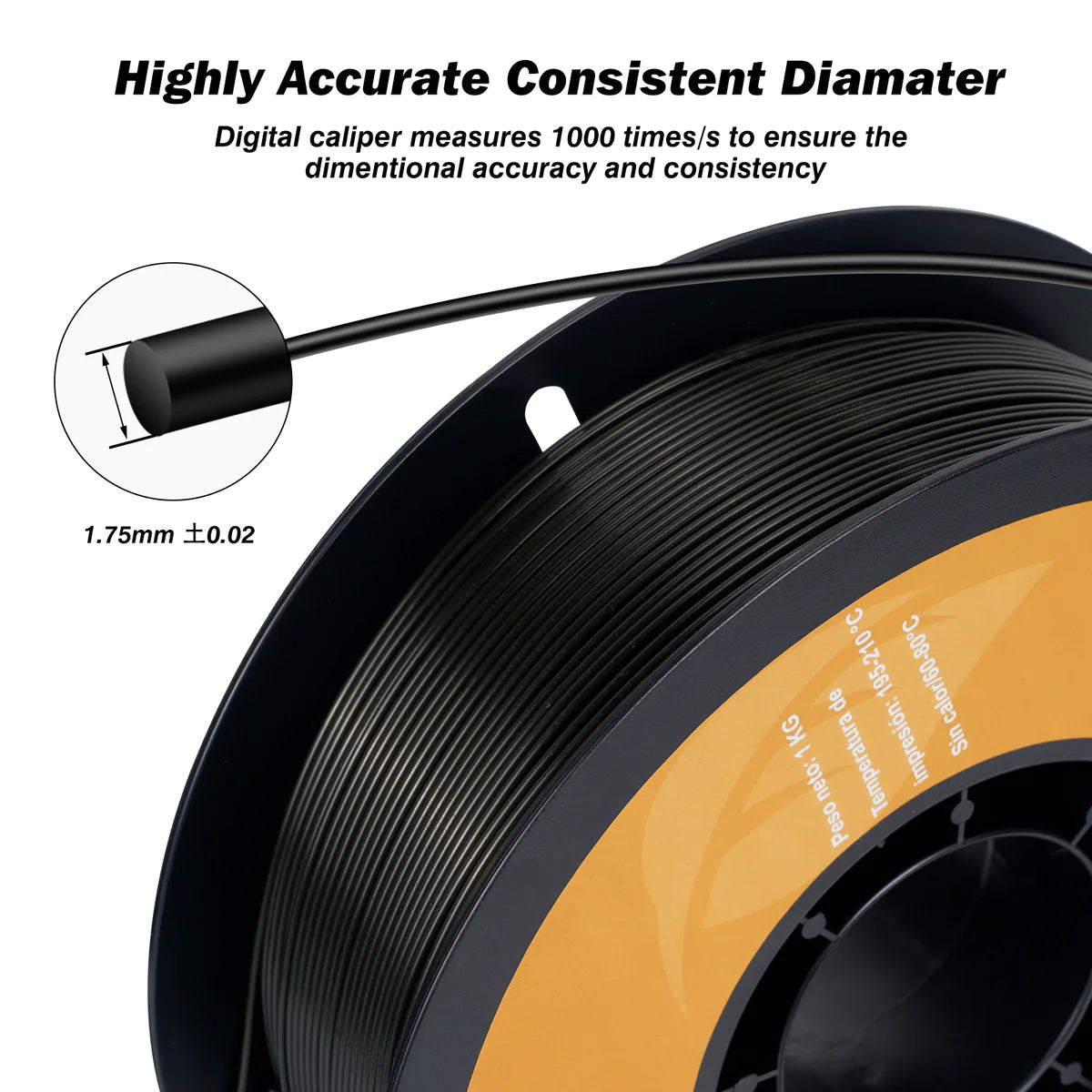

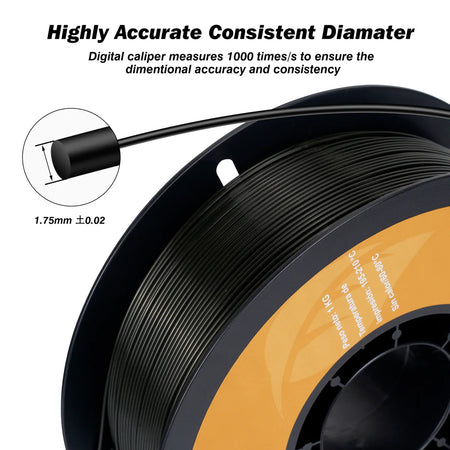

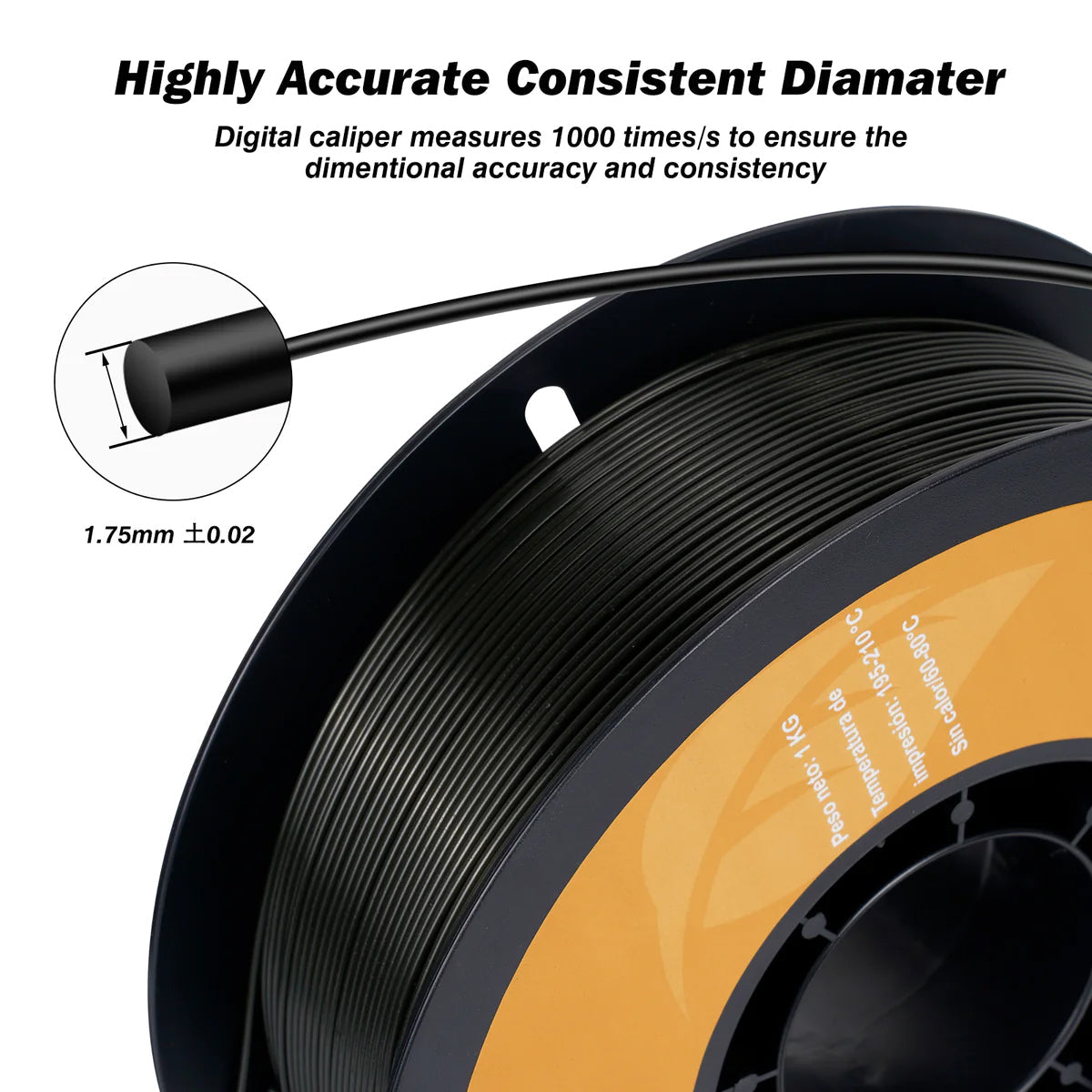

Filament Specifications:

1.75mm +/- 0.05mm in diameter

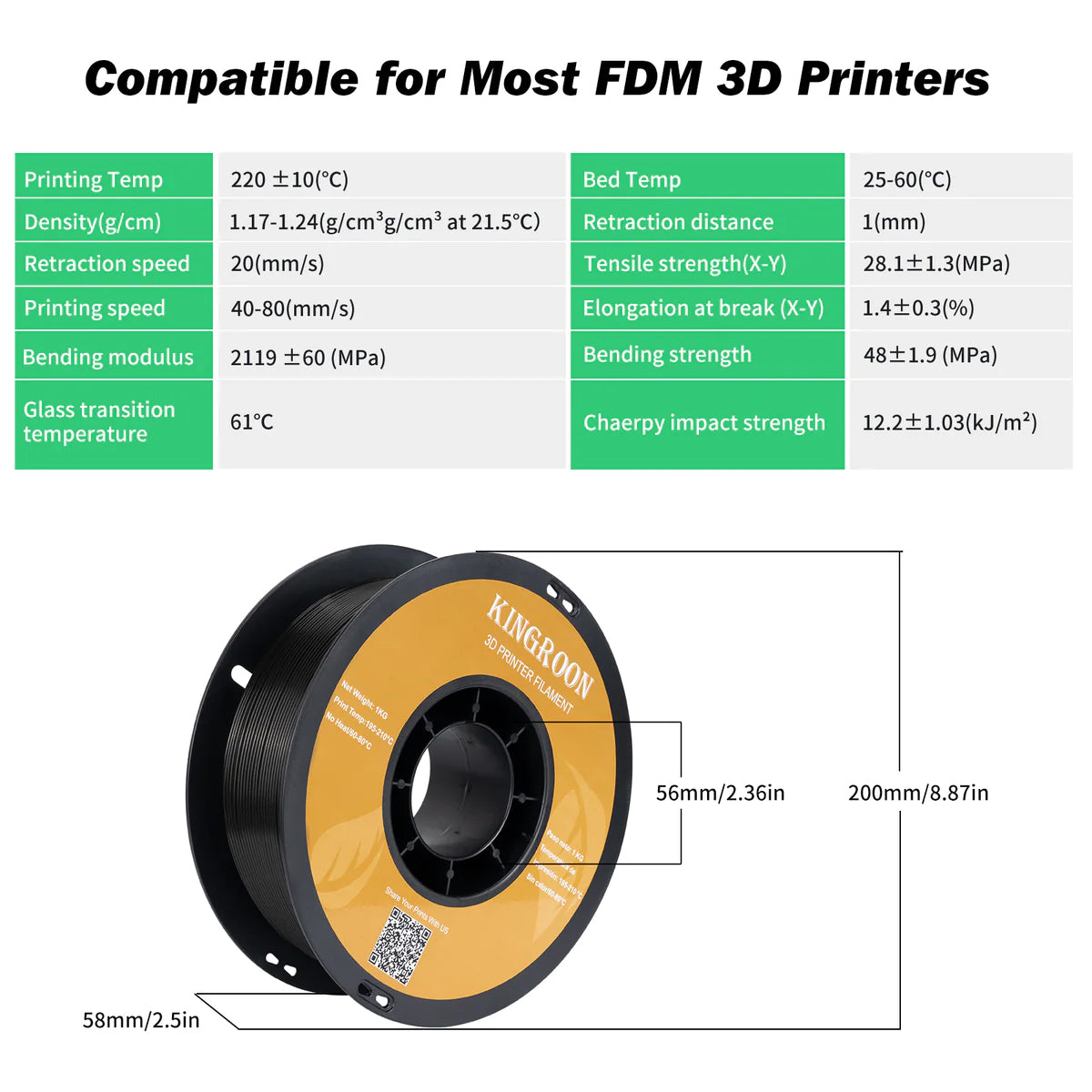

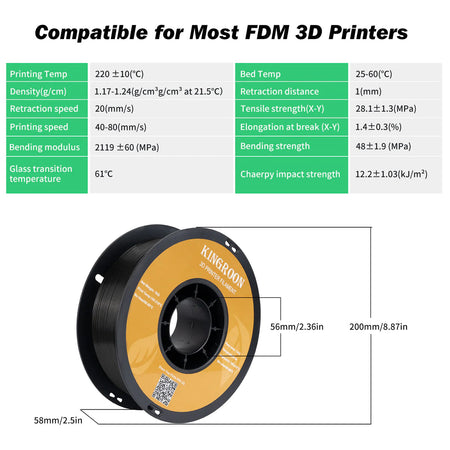

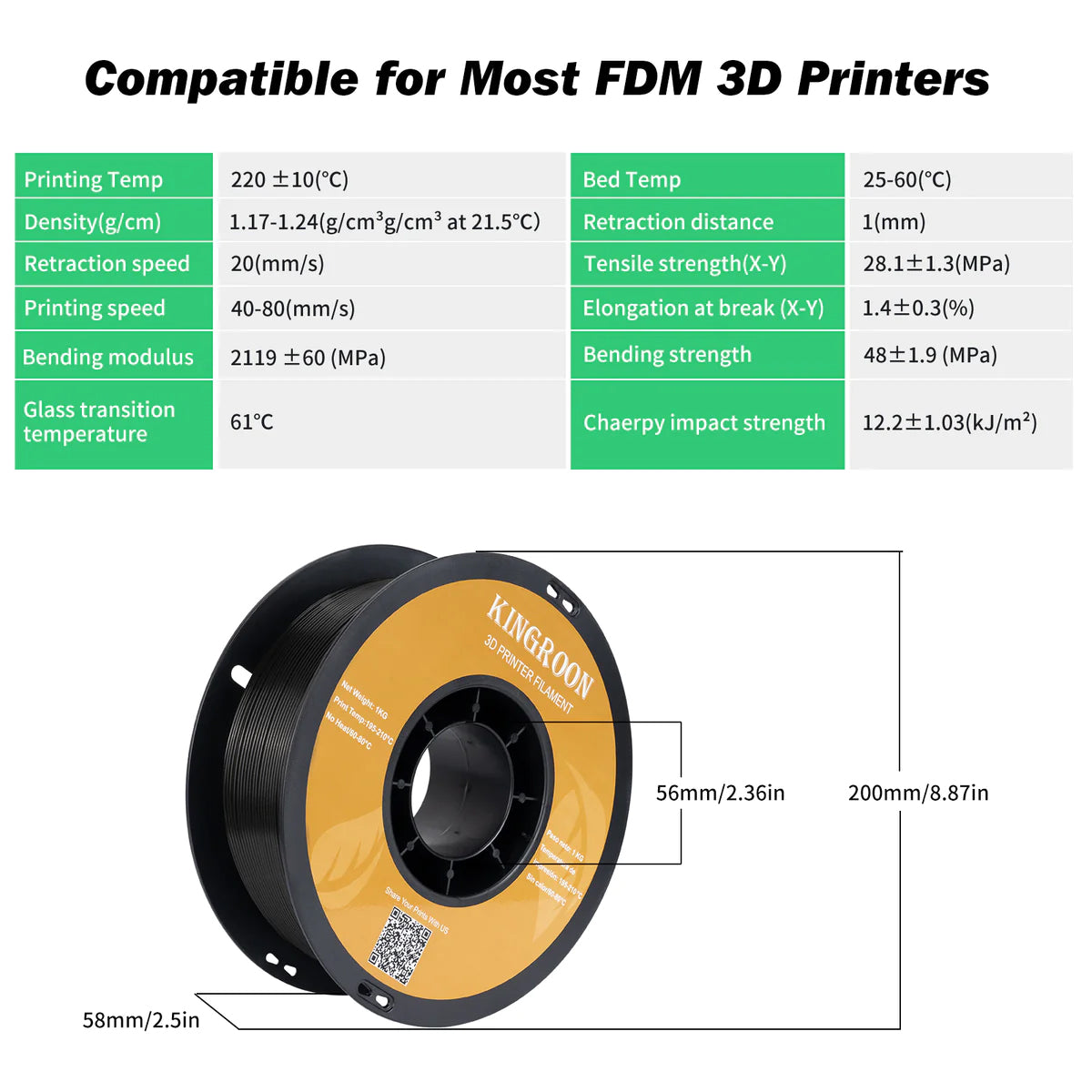

Recommended Print Settings:

• Extruder Temperature: 235-260℃,

• Bed temperature: 80-105℃

• Printing Speed: 40-100mm/s

• Heated Bed: Required

• Recommended Build Surfaces: PVP Soild Glue + 3Dlac, always use brim for better bed adhesion.

• Print Suggestion: Drying at 65℃ />3h

• Other recommendations: cover around printer, protection against change of ambient temperature.

More information of Nylon-CF

CLICK HERE| PLA | PETG | Rapid PLA | |

|---|---|---|---|

| RECOMMENDED NOZZLE TEMP: | 190°C - 220°C (recommended 205°C) |

220-260°C (recommended 220°C) |

200-230°C (recommended 220°C) |

| RECOMMENDED HEATED BED TEMP: | 50-65°C | 80-80°C | 40-60°C |

| PRINTING SPEED: | 30~70mm/s | 30~600 mm/s | 30~600 mm/s |

| PRINT LAYER THICKNESS: | 0.2mm | 0.2mm | 0.2mm |

| RECOMMENDED PLATFORM: | Glass/Fiberglass Board/PVP glue stick or textured paper | Glass/Fiberglass Board/PEI+PVP glue stick or platform spray | Glass/Fiberglass Board/PEI+PVP glue stick or platform spray |

| DIMENSIONAL ACCURACY 99% PROBABILITY: | +/- 0.02mm | +/- 0.02 mm | +/- 0.02 mm |

| NET WEIGHT: | 1 kg/spool (2.2 lbs) | 1 kg/spool (2.2 lbs) | 1 kg/spool (2.2 lbs) |

| DENSITY: | 1.2(g/cm³) | 1.27(g/cm³) | 1.2(g/cm³) |

| TENSILE STRENGTH (X-Y) : | ≥ 50(MPa) | ≥60(MPa) | ≥60(MPa) |

| ELONGATION AT BREAK (X-Y) : | 11.2 (%) | 19 (%) | 19 (%) |

| BENDING MODULUS : | 1913(MPa) | 2680(MPa) | 2680(MPa) |

| BENDING STRENGTH : | 91(MPa) | 80(MPa) | 80(MPa) |

| CHARPY IMPACT STRENGTH : | 5.4(kJ/m²) | 3.85 (KJ/m²) | 3.85 (KJ/m²) |

| MELT INDEX: | 14(190℃/2.16kg)g/10min | 8.2(190°C/2.16kg)g/10min | 8.2(190°C/2.16kg)g/10min |

| THERMAL DISTORTION TEMP: | 53°C (0.45MPa) | 53°C (0.45MPa) | 53°C (0.45MPa) |

| FAN: | 100% | 100% | 100% |

| ROCKWELL HARDNESS: | 88 | 88 | 88 |