Induction Hotend Silicone Sleeve for H2C Bambu Lab

No se pudo cargar la disponibilidad para recoger

Utilice este texto para fomentar la comunicación o promover el intercambio en las redes sociales.

The Induction Hotend Sillicon Sleeve is made from high-quality silicone for higher temperature resistance. Ensuring optimal thermal insulation and tear resistance, the silicone sleeve also provides the nozzle with long-lasting protection from cooling air and plastic adhesion.

In the Box

- Induction Hotend Sillicon Sleeve *3

Compatibility

H2C and H2C Laser

Induction Hotend Silicone Sleeve Replacement Guide for H2C

This article will provide you with a detailed guide on the step-by-step process and important considerations for replacing the Induction Hotend Silicone Sleeve on your H2C.

Induction Hotend Silicone Sleeve

The silicone sleeve on the induction hotend, which covers the head of the induction hotend, serves the primary function of keeping the nozzle area warm and isolating impurities, preventing the filament from soiling the nozzle and affecting print quality.

When to Use This Guide

The silicone sleeve of the induction hotend is damaged, cracked, or deformed due to aging.

Safety Warning

It's crucial to power off the printer before conducting any maintenance work, including work on the printer's electronics and tool head wires. Performing tasks with the printer on can result in a short circuit, leading to electronic damage and safety hazards.

During maintenance or troubleshooting, you may need to disassemble parts, including the hotend. This exposes wires and electrical components that could short circuit if they contact each other, other metal, or electronic components while the printer is still on. This can result in damage to the printer's electronics and additional issues.

Therefore, it's crucial to turn off the printer and disconnect it from the power source before conducting any maintenance. This prevents short circuits or damage to the printer's

Removing the Old Induction Hotend Silicone Sleeve

Step 1: Locate the Gap Below at the Hotend

Step 2: Lift Along the Notch to Remove the Old Silicone Sleeve Easily

Step 2: Lift Along the Notch to Remove the Old Silicone Sleeve Easily Installing the New Silicone Sleeve on the Induction Hotend

Installing the New Silicone Sleeve on the Induction Hotend

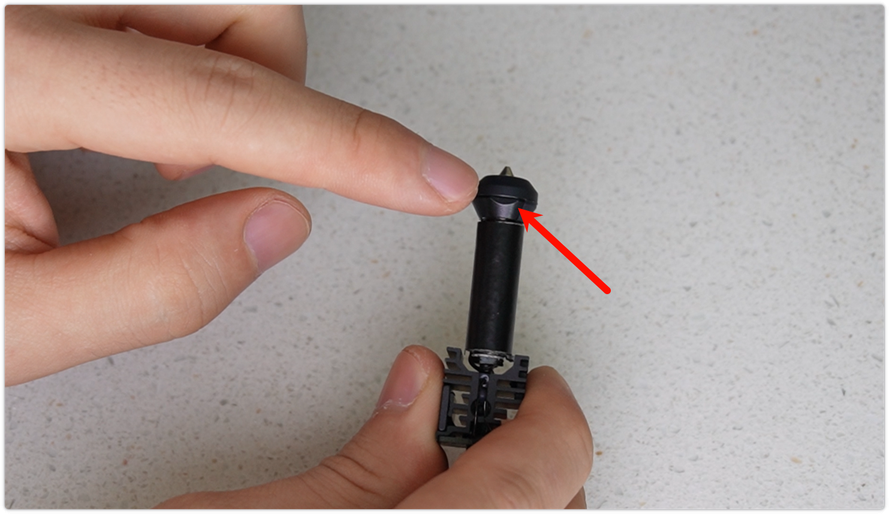

Step 1: Locate the Positioning Groove on the Induction Hotend

Locate the groove along with the corresponding protrusion on the silicone sleeve, then align them.![]()

Step 2: Align the Protruding Part of the Silicone Sleeve With the Groove on the Hotend and Press it in

Then, press both sides of the silicone sleeve together to hold it in place.

Step 3: Slowly Rotate the Silicone Sleeve While Applying Even Inward Pressure to Ensure a Secure Fit

Step 4: Check the Silicone Sleeve for Any Raised Parts

Step 4: Check the Silicone Sleeve for Any Raised Parts

If any are found, press them into the corresponding grooves on the hotend to complete the installation.

Verifying Functionality

Verifying Functionality

The result after installation should look like this.

![]()