Kingroon KP3S Pro V2 - Klipper Firmware Installed Impresora 3D

Couldn't load pickup availability

Use this text to encourage communication or promote sharing on social networks.

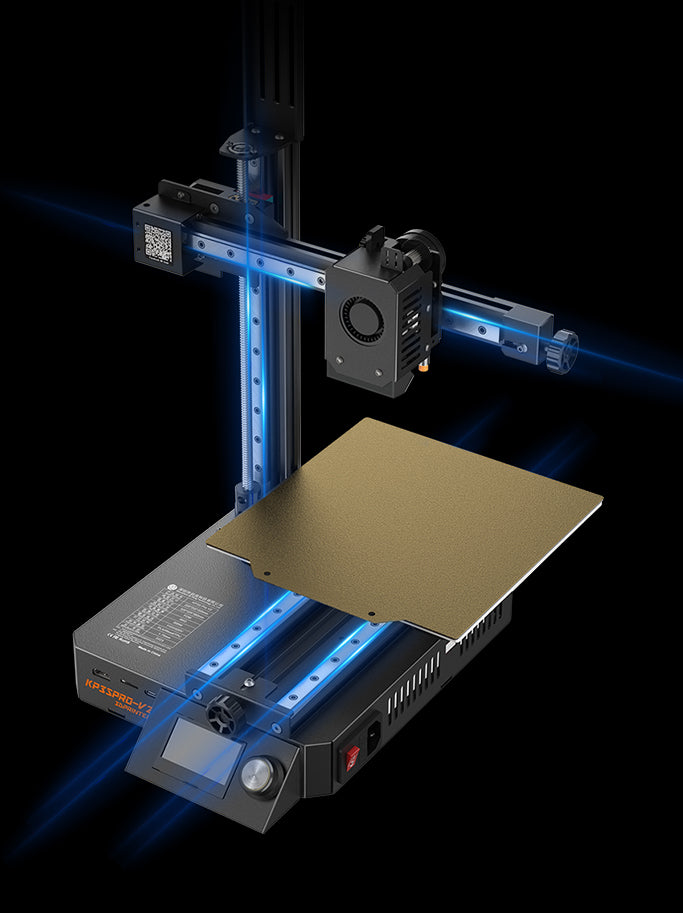

Kingroon KP3S Pro V2 is a fast-print-speed Impresora 3D with Klipper firmware installed. It makes Klipper becomes reachable, affordable, and usable for everyone. With the Klipper features, it let people print at high speed and with great quality.

· All-in-one Klipper Mainboard

KP3S Pro V2 has a powerful mainboard with Klipper firmware installed. No Raspberry Pi is required.

· 350mm/s High-Speed Print

High-quality print with less waiting time. KP3S Pro V2 has 350mm/s high-speed printing & 10000mm/s² acceleration. The built-in ADXL345 module ensures you high-quality print under fast print speed with active vibration compensation.

· Linear Rail Guides on All Axis

KP3S Pro V2 has linear rail guides on X, Y, and Z axis, which makes your printer more stable and durable in fast movements.

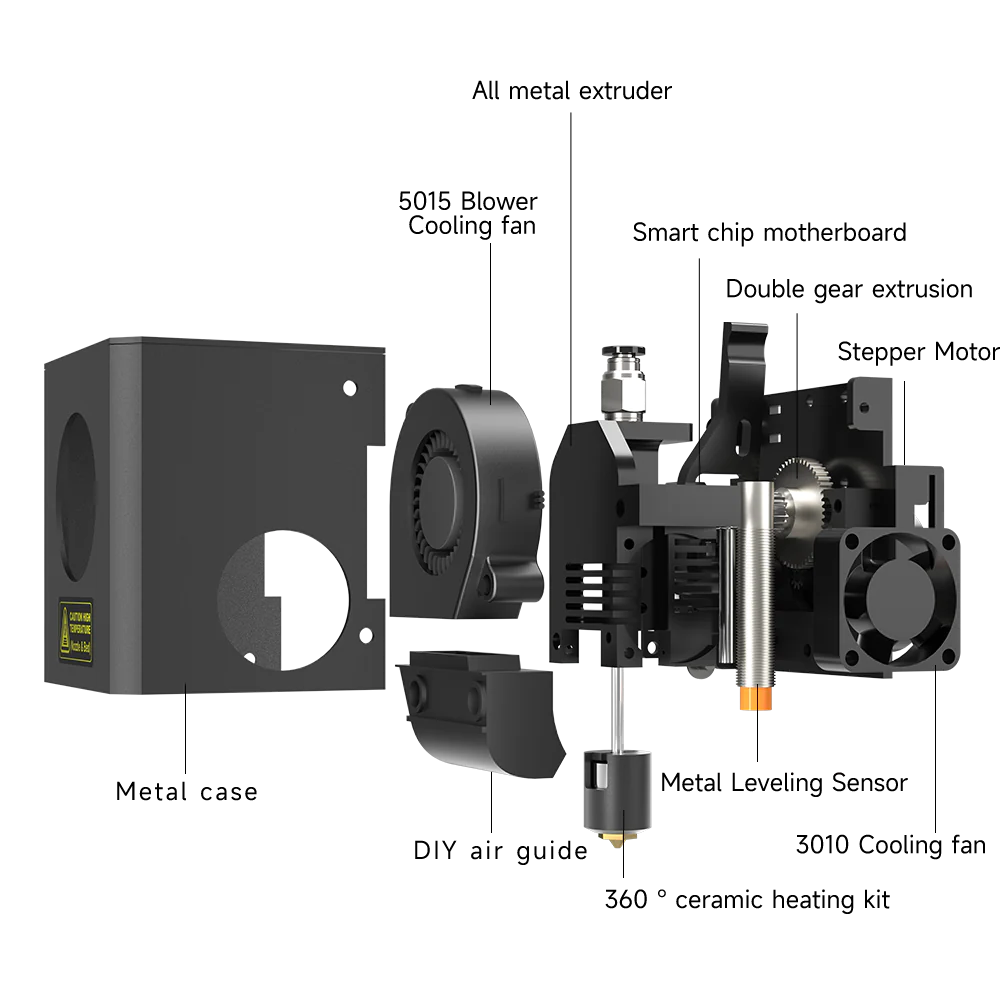

· 5:1 Gear Ratio

5:1 Gear Ratio, all metal, 8000 ring 5015 fan, smart micro processors, the new extruder means powerful extrusion and better cooling system.

· Multi Interface Options

With the Internet connection, any screen can be your printer screen, you can control KP3S Pro V2 anyhow, anytime and anywhere.

· Auto Bed Leveling

The auto bed leveling comes to KP3S Pro V2, with its new bed structure, it’s fully ABL.

· Volúmen de construcción: 210x210x210mm

· Filamentos: PLA, TPU, ABS, PETG, Nylon CF

· Extrusor: Direct

Kingroon KP3S Pro V2 Reviews

KP3S PRO V2 Review from Aurora Tech

Fast Klipper 3D printer: KP3S Pro V2

Why Klipper?

Web interface and Wi-Fi integration

Klipper offers a user-friendly web interface that allows you to easily control and monitor your 3D printer remotely. Additionally, it seamlessly integrates with Wi-Fi, enabling wireless connectivity and enhancing convenience.

High speed printing

Klipper is known for its impressive printing speed. By offloading complex calculations to the host computer instead of relying solely on the printer's microcontroller, Klipper can execute print commands and movements with greater efficiency, resulting in faster print times.

Feature set

Klipper offers an extensive range of features, including advanced motion control algorithms, kinematics options, and flexible support for a variety of 3D printer hardware configurations. These features provide users with enhanced control and capabilities for optimizing their printing experience.

Input Shaper

Input shaping is a technique used to address resonance compensation. Resonance in 3D printing refers to the vibrations or oscillations that occur when the printer rapidly changes direction. These vibrations can lead to imperfections in the printed object, such as ghosting or ringing. The faster the printer moves, the more prominent these resonance effects become.

To combat these artifacts and improve print quality, input shaping techniques can be used. Input shaping is a method that aims to minimize the impact of resonance and other related problems on 3D prints. By shaping or modifying the input commands to the printer, the vibrations and artifacts can be reduced, leading to better print results.

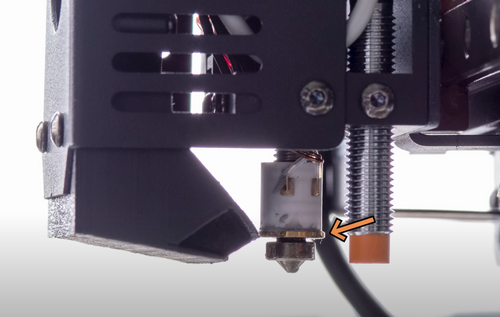

All Metal Hotend

KP3S Pro V2 has a new extruder with a modified print head. The extruder is equipped with large feeding wheels with 5:1 gear ratio, a ceramic heater, and a solid metal throat, that support 300 degree high temp print. The direct extruder are designed for printing flexible materials, like TPU.

The smart micro processors and 8000 ring 5015 fan ensures a powerful extrusion and better cooling system.

Fast heating and high-speed all-metal extruder.5:1 Gear ratio extrusion structure, 5 times the extrusion ratio, greater extrusionforce.All metal hotend that supports 300 degree high temp print. The direct extruder are designed for printing flexible materials, like TPU.The smart micro processors and 8000 ring 5015 fan ensures a powerful extrusion and better cooling system.

Linear Rail Guides on All Axis

KP3S Pro V2 has linear rail guides on X, Y, and Z axis, which makes your printer more stable and durable in fast movements.

Kingroon KP3S Pro V2 Downloads

Kingroon KP3S Pro V2 Tutorial Video

KINGROON KP3S PRO V2 Unboxing / Assembly

Screen Control of the KINGROON KP3S Pro V2

FAQ of Kingroon KP3S Pro V2

Kingroon KP3S Pro V2 Técnicas Specifications

| Product Model | Kingroon KP3S Pro V2 | Nozzle Max Temperature | ≤260 C(default)-300C |

|---|---|---|---|

| Technology | FDM | Heated Bed Max Temperature | ≤100 C |

| Print Volume | 200*200*200mm | Max Movement Speed | ≤500mm/S |

| Print Bed Size | 210*210mm | Max Printing Speed | ≤500mm/S |

| Machine Size | 345*330*506mm | Recommended Printing Speed | 200mm-350mm/S |

| Packaging Size | 510*440*200mm | File Format | STL/Obj/Gcode |

| Net Weight | 6kg | Auto Leveling | Support |

| Language Firmware | CN/EN Klipper | Material Break Detection | Optional |

| Print Via | Web/USB Flash Disk | Power Off And Continue Printing | Temporarily Not Supported |

| Machine Power | 200W | System Requirement | Win7-10/Mac/Linux |

| Input Voltage | 110V-220V | Slicing Software | Cura/Slice/Host... |

| Power Supply | 24V 12.5A 300W | Nozzle diameter | 0.4mm |

| Feeder System | Full-Metal Hotend | Nozzle Model | Hardened Steel E3D V6 |

| Printing Accuracy | 0.05-0.3mm | Print Bed | Heat Bed With PEI Sheet |