Kate G. - July 6 2025

A1 Mini Swapmod Assembly Tutorial

Assembly Instructions

1·Insert both ends of the bracket into the rear component as shown in the diagram.

2·Push the front component to the front of the printer's Y-axis and check if it is secure.

3·Fix the Z-axis component. When removing, press the clasp at the red circle to detach the component.

4·Install the binding device and rotate it to the position shown in the diagram.

5·Install the heated bed clip.

Tighten the buckle in the red circle to secure the heating bed.

6·Install the tray. Lift the printer and then secure it behind the printer's Y-axis. Be careful not to press on the wires.

7·Install the heated bed printing plate. Align the notch of the clip with the notch of the heated bed for installation. Finally, tighten the screws.

PEI sheet holder stl file to download:

https://drive.google.com/drive/folders/18mria-JTUFUnxbvAUMf-lE-0ydRcNZcf?spm=5261.27096742.0.0.401d4743UBeuZU&usp=sharing

Note: When printing, the two protruding parts at the bottom of the bracket should face down.

8·Use your hands to push the heated bed for testing. Ensure that the heated bed steel plate can be replaced smoothly.

Continuous Multi-Plate Printing Operation Software Description

Tutorial on how to use multi-plate printing test files

1·To access this website, you can download the test files for continuous multi-plate printing.

2·Open [Bambu Studio], drag the 3mf file into the slicing software, and proceed to print. This will allow you to test.

Note: Before printing, please click on the [XYZ Axis Zeroing] on the printer screen, and then proceed with printing.

User Manual for Multi-Plate Printing Software

1·Export all the sliced models and save them to the computer.

2·Open the website: https://swaplist.app

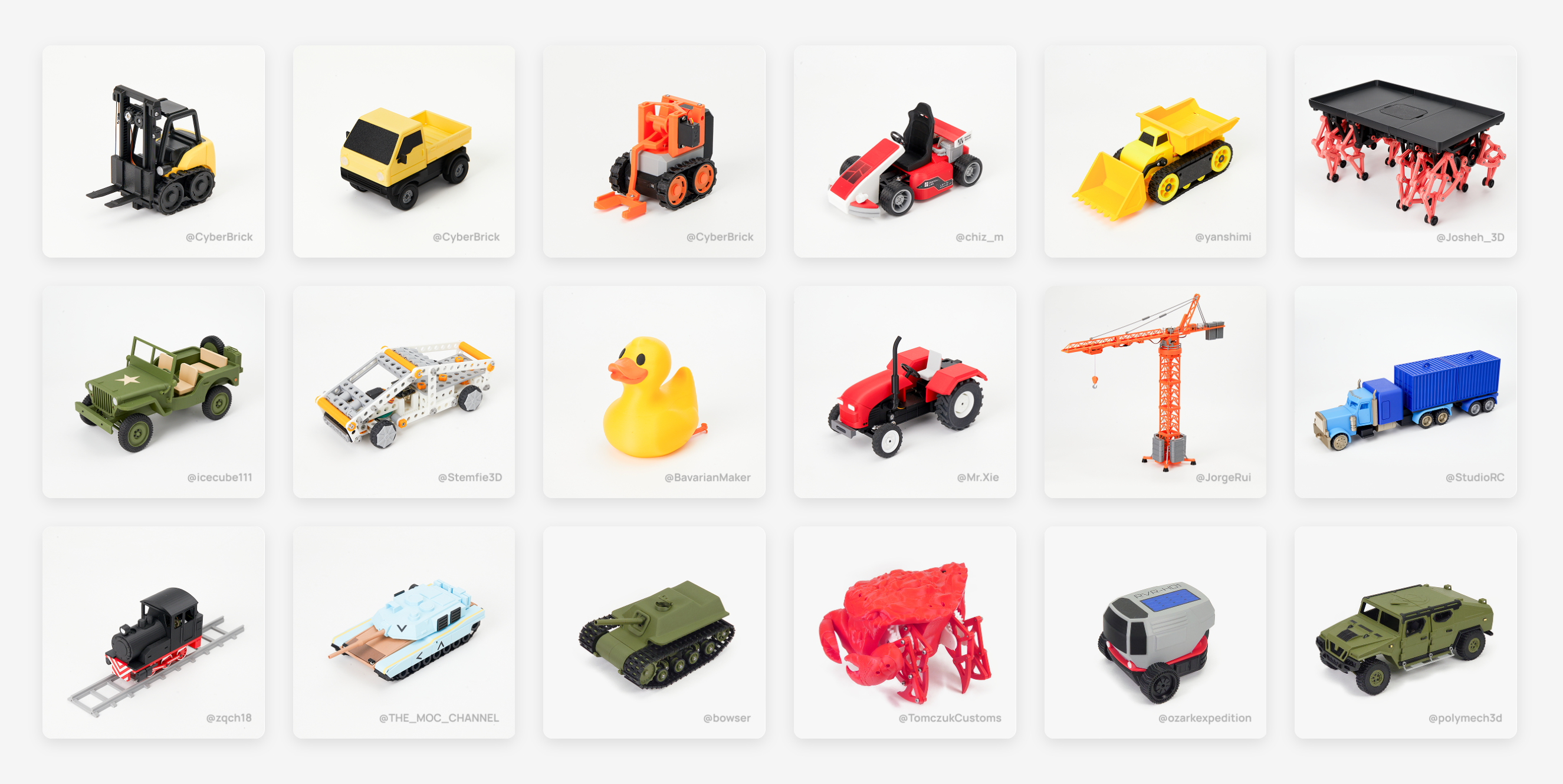

Then drag the file to the area shown in the image here.

3·We will see the inserted slice files. If we want to print two plates of the model, we can change the value to 2.

4·If we wish to print a larger quantity, we can click on the [Settings] option to make adjustments.

5·Click on the red circle in the image to export the file to your computer.

6·Using [Bambu Studio] software, open the file and then print. The printer will print models of multiple print boards.

Note: Before printing, please click on the [XYZ Axis Zeroing] on the printer screen, and then proceed with printing.