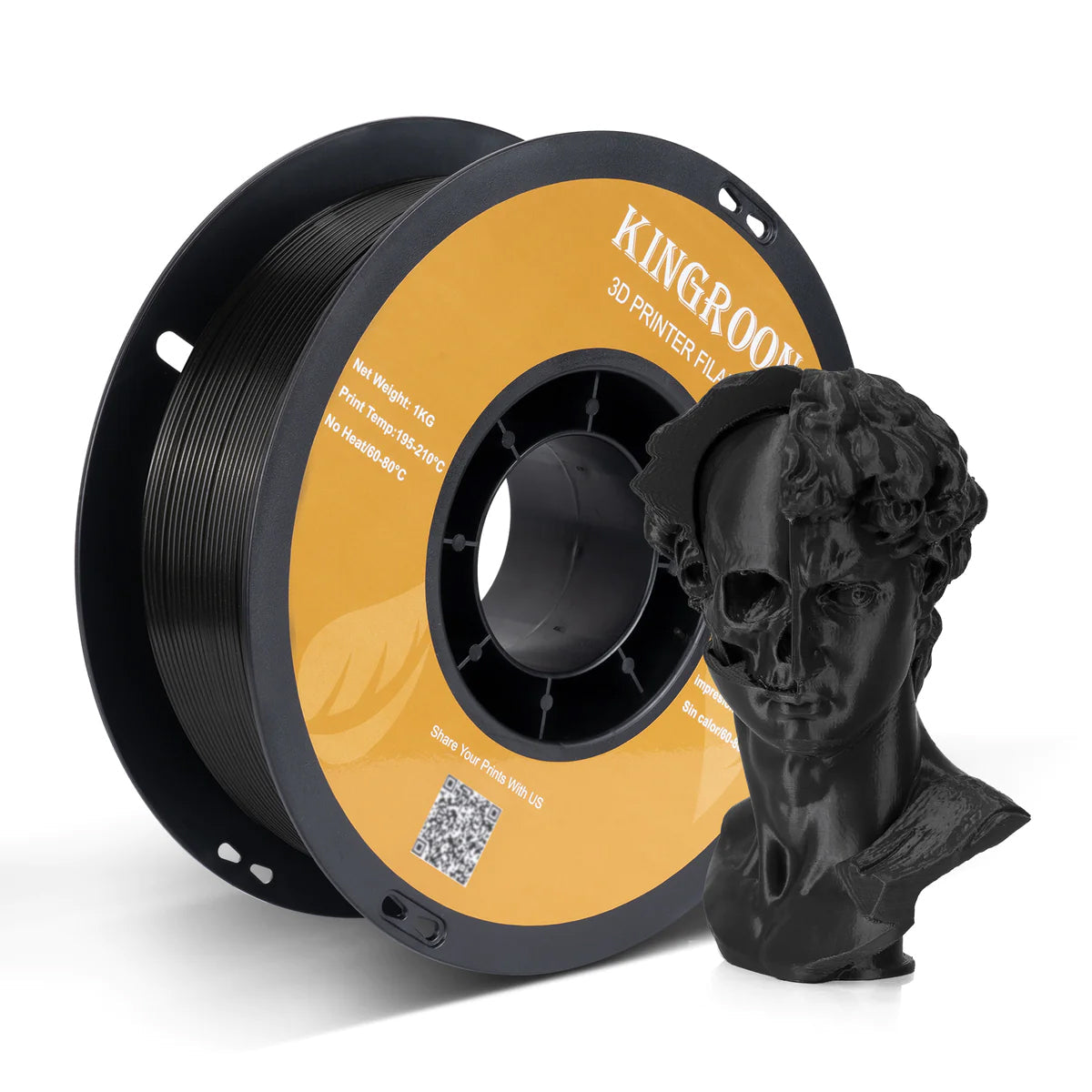

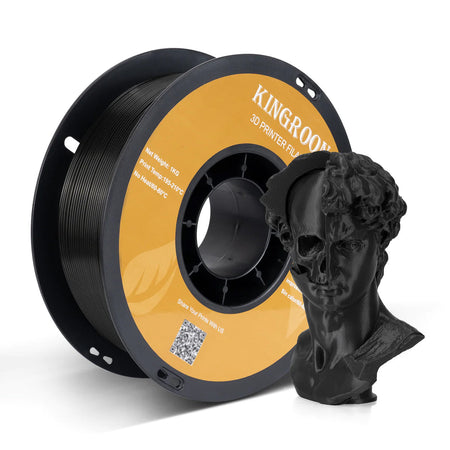

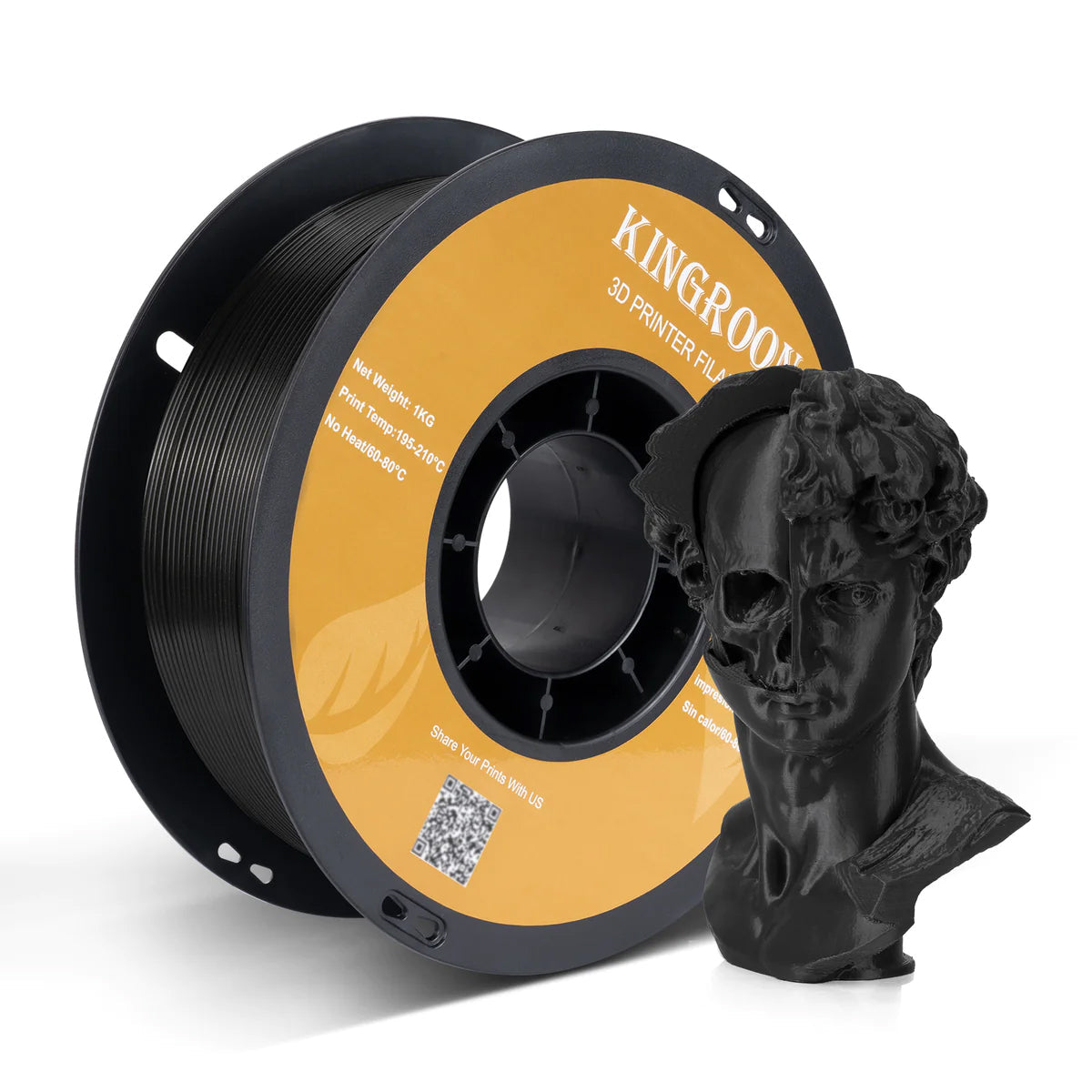

PA+CF Carbon Fiber Nylon 3D Filament, 1 KG

Couldn't load pickup availability

Use this text to encourage communication or promote sharing on social networks.

PA-CF Carbon Fiber Nylon 3D Filament is made using a specialty Nylon copolymer and high-modulus carbon fiber. This is the go-to material for industrial applications that require superior thermal, mechanical, and chemical resistance properties while retaining the ease of printing that you’ve come to expect.

Nylon CF Printing Tips

- Like all nylons, Nylon CF must be kept dry! If it does not remain packaged with desiccant, it will readily absorb moisture from the air; this will lead to degraded print quality and wasted filament. You can dry it out by using a filament dryer for more precise dehydration for all filament types.

- It's necessery to use an all-metal hot end when printing with carbon firber filaments. Micro Swiss offers an all-metal hot end, but alternatives like those from E3D or Slice Engineering are also viable options. It's essential to upgrade the nozzle as well. The brass or the plated copper nozzles are not suitable for abrasive materials. Instead, options like hardened steel, ruby-tipped, Creality Unicorn Tri-Metal nozzle or Nozzle X from E3D are recommended for printing with abrasives. The market has increased prevalence of enclosed consumer-grade 3D printers equipped with hardened extruders and nozzles capable of handling such materials, such as Creality K1C, Bambu X1, X1C, etc.

Package includes

1 roll of filliment, 1KG per roll.

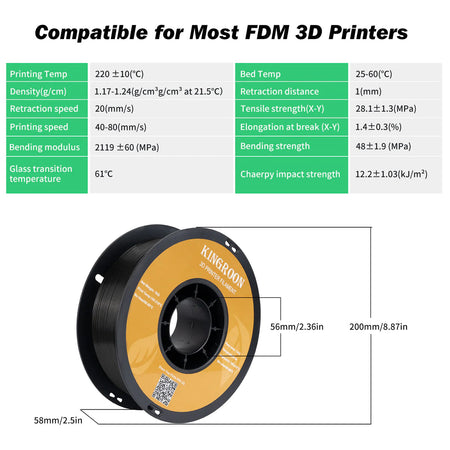

Filament Specifications:

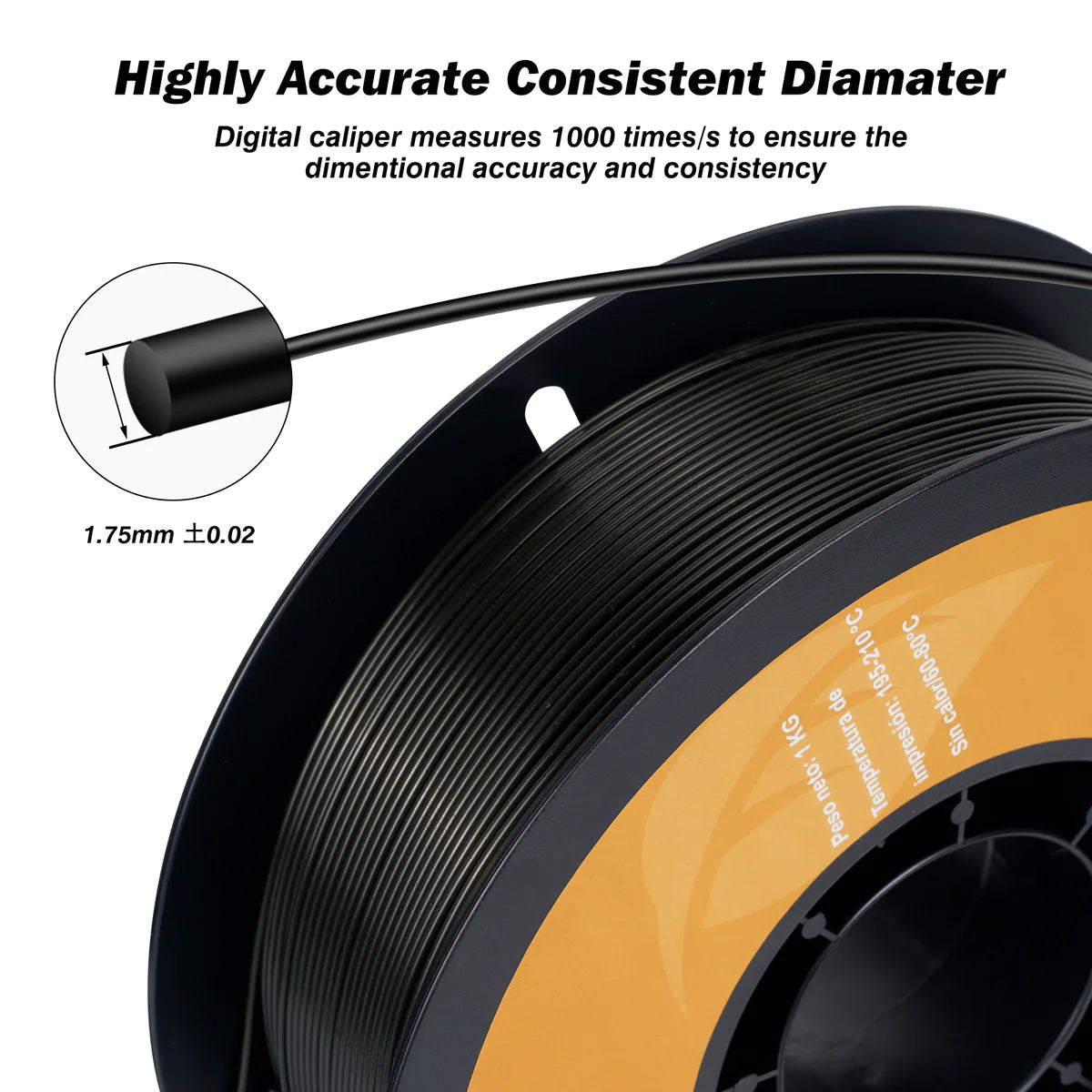

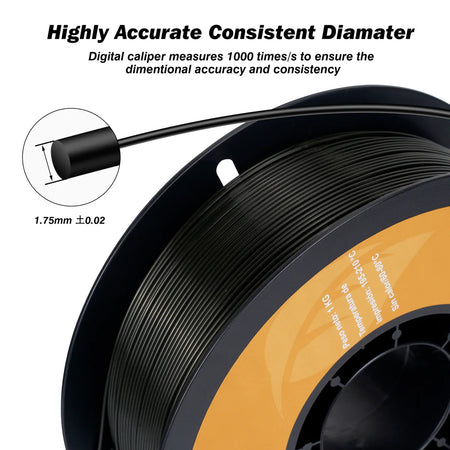

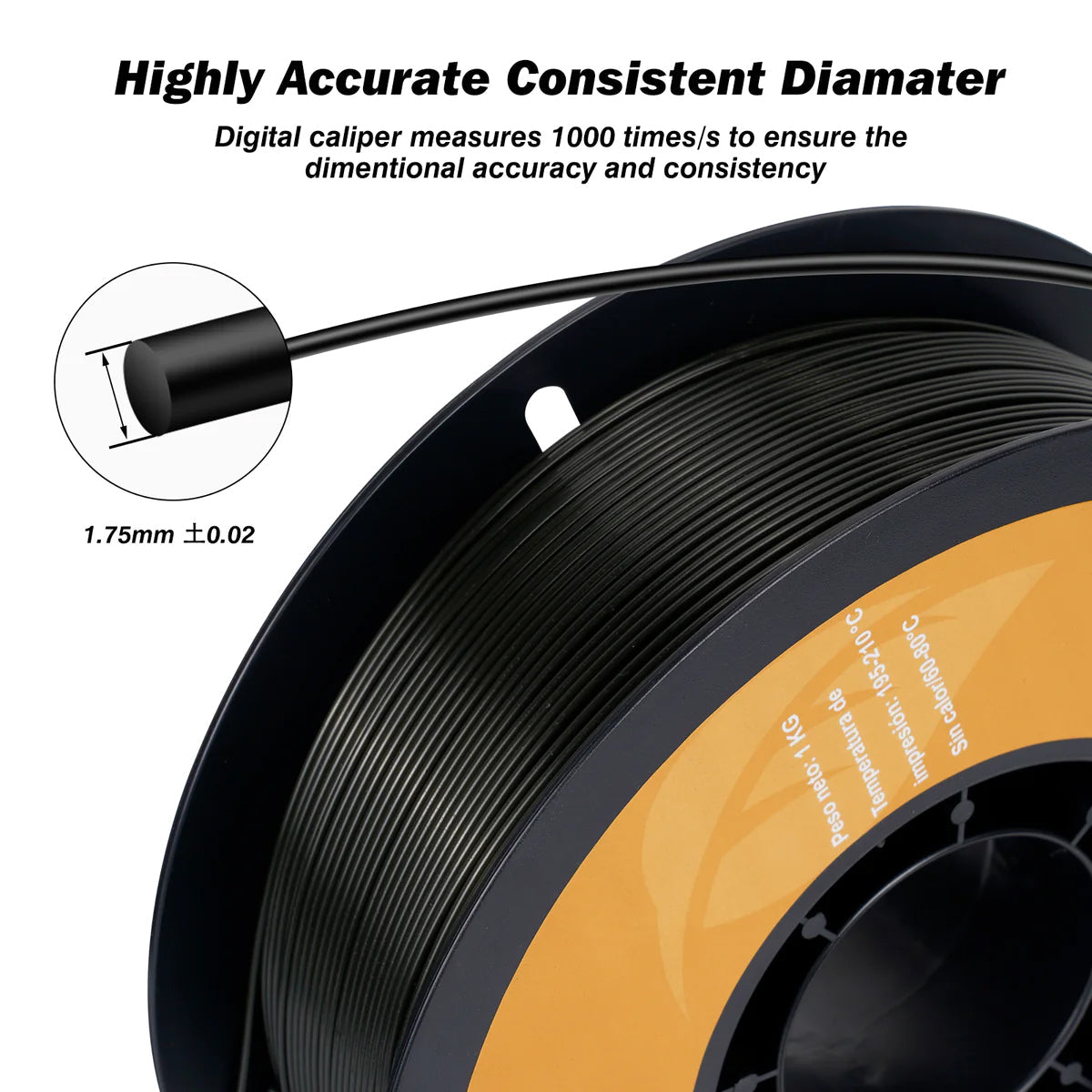

1.75mm +/- 0.05mm in diameter

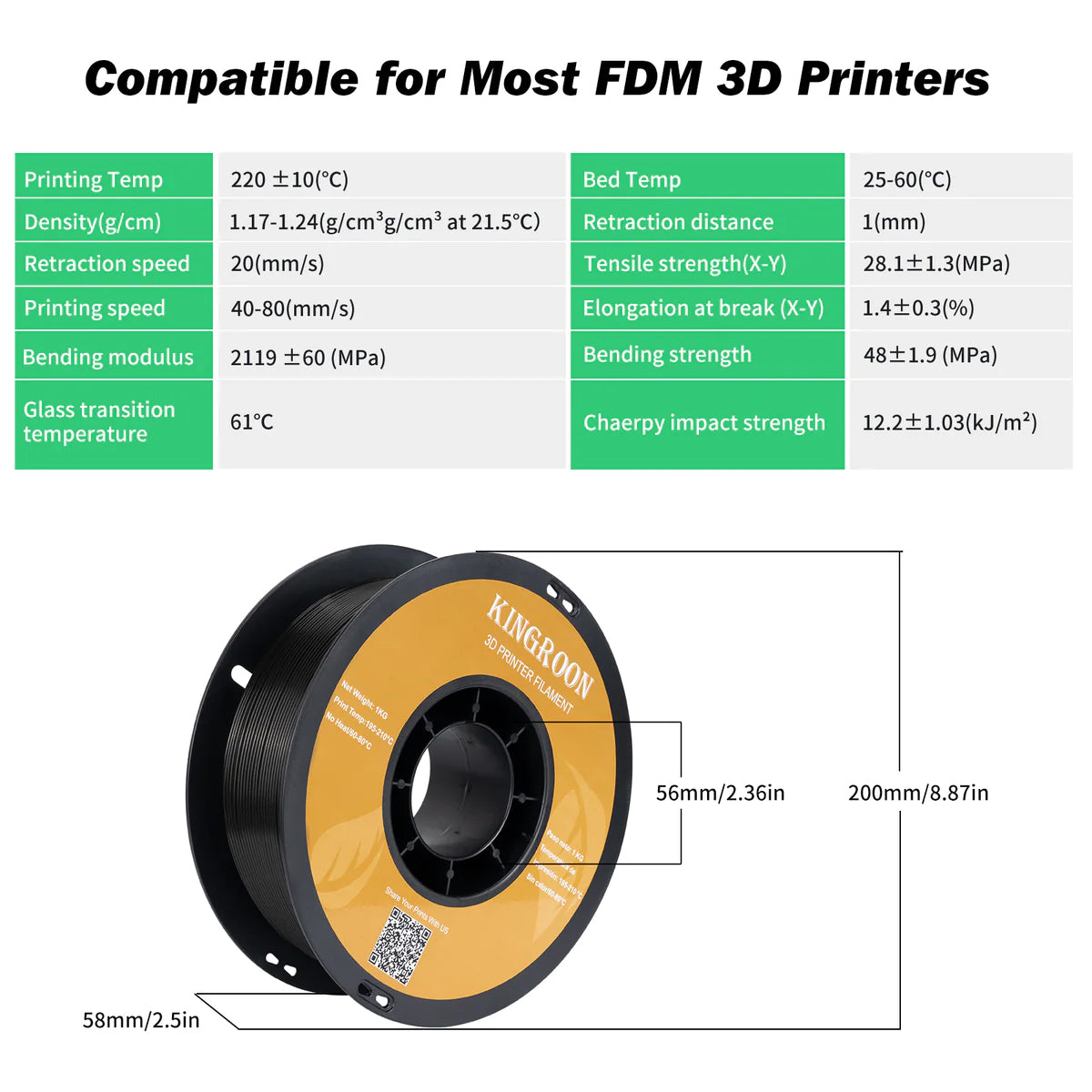

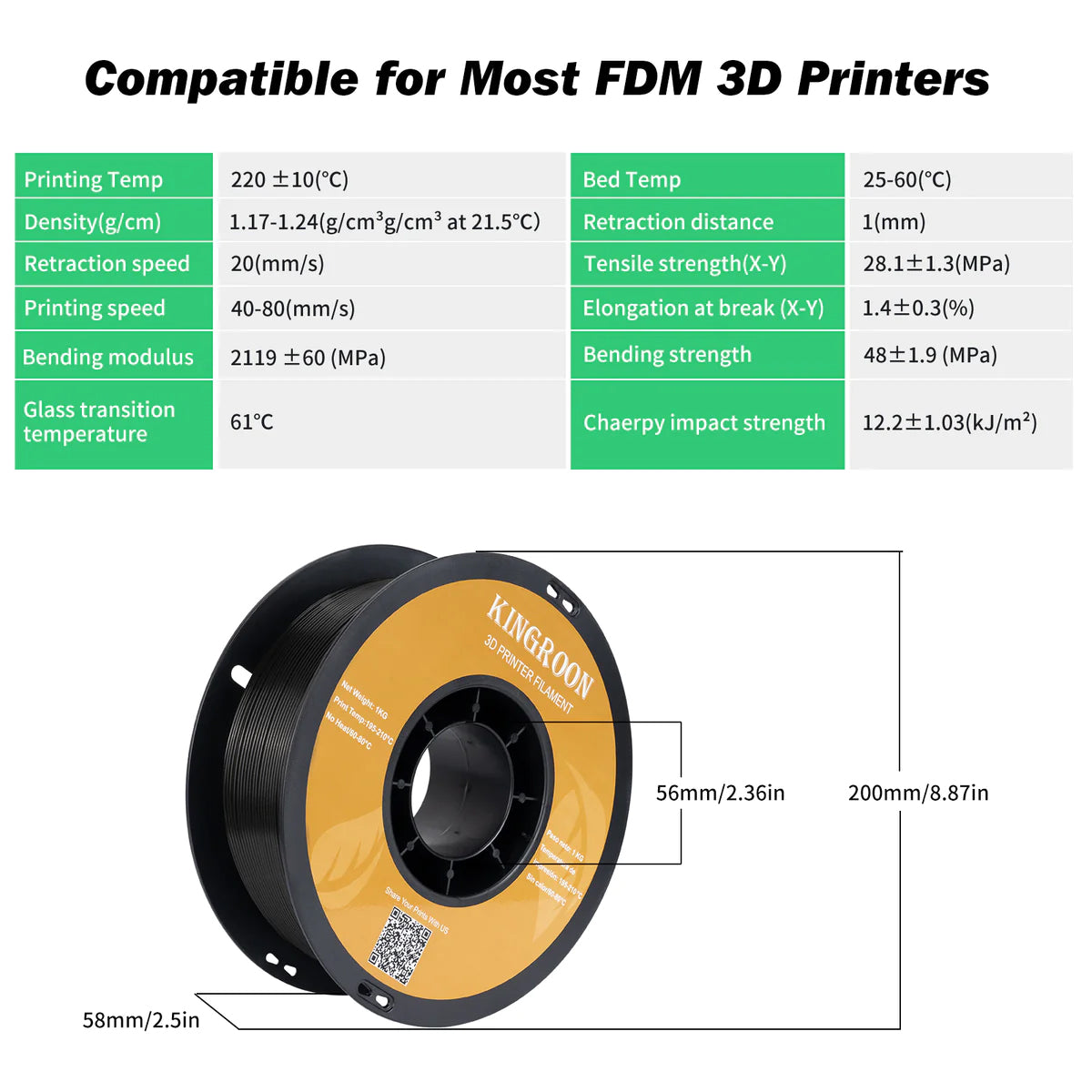

Recommended Print Settings:

• Extruder Temperature: 235-260℃,

• Bed temperature: 80-105℃

• Printing Speed: 40-100mm/s

• Heated Bed: Required

• Recommended Build Surfaces: PVP Soild Glue + 3Dlac, always use brim for better bed adhesion.

• Print Suggestion: Drying at 65℃ />3h

• Other recommendations: cover around printer, protection against change of ambient temperature.

More information of Nylon-CF

CLICK HERE| PLA | PETG | Rapid PLA | |

|---|---|---|---|

| RECOMMENDED NOZZLE TEMP: | 190°C - 220°C (recommended 205°C) |

220-260°C (recommended 220°C) |

200-230°C (recommended 220°C) |

| RECOMMENDED HEATED BED TEMP: | 50-65°C | 80-80°C | 40-60°C |

| PRINTING SPEED: | 30~70mm/s | 30~600 mm/s | 30~600 mm/s |

| PRINT LAYER THICKNESS: | 0.2mm | 0.2mm | 0.2mm |

| RECOMMENDED PLATFORM: | Glass/Fiberglass Board/PVP glue stick or textured paper | Glass/Fiberglass Board/PEI+PVP glue stick or platform spray | Glass/Fiberglass Board/PEI+PVP glue stick or platform spray |

| DIMENSIONAL ACCURACY 99% PROBABILITY: | +/- 0.02mm | +/- 0.02 mm | +/- 0.02 mm |

| NET WEIGHT: | 1 kg/spool (2.2 lbs) | 1 kg/spool (2.2 lbs) | 1 kg/spool (2.2 lbs) |

| DENSITY: | 1.2(g/cm³) | 1.27(g/cm³) | 1.2(g/cm³) |

| TENSILE STRENGTH (X-Y) : | ≥ 50(MPa) | ≥60(MPa) | ≥60(MPa) |

| ELONGATION AT BREAK (X-Y) : | 11.2 (%) | 19 (%) | 19 (%) |

| BENDING MODULUS : | 1913(MPa) | 2680(MPa) | 2680(MPa) |

| BENDING STRENGTH : | 91(MPa) | 80(MPa) | 80(MPa) |

| CHARPY IMPACT STRENGTH : | 5.4(kJ/m²) | 3.85 (KJ/m²) | 3.85 (KJ/m²) |

| MELT INDEX: | 14(190℃/2.16kg)g/10min | 8.2(190°C/2.16kg)g/10min | 8.2(190°C/2.16kg)g/10min |

| THERMAL DISTORTION TEMP: | 53°C (0.45MPa) | 53°C (0.45MPa) | 53°C (0.45MPa) |

| FAN: | 100% | 100% | 100% |

| ROCKWELL HARDNESS: | 88 | 88 | 88 |