3D High Quality MK8 Nozzle for 3D Printers parts 1.75mm Filament Hardened Steel Nozzle M6 Thread

Couldn't load pickup availability

Use this text to encourage communication or promote sharing on social networks.

【HIGH QUALITY MK8 NOZZLE】

High quality processing manufacturing, this nozzle has higher toughness and hardness. The inner wall of the MK8 nozzles is smooth and has no burrs.Ensure the printing have an accurate and smooth extrusion.

Material Brass

High quality brass providing smooth layers for standard non-abrasive applications. Heavy duty and provide a long service life.

Material Copper plating

Our unique plated copper nozzles are suitable for high-temperature, non-abrasive applications. The nickel plating provides a reduced-stick surface, ideal for situations where temperatures are too hot for a silicone sock. Rated to a maximum temperature of 550°C.

Material Hardened steel

nozzles are made of hardened tool steel.better abrasion resistance, heat resistance and corrosion resistance that suitable for 3D printing at high temperature filaments, like Nylon CF. Rated to a maximum temperature of 500°C

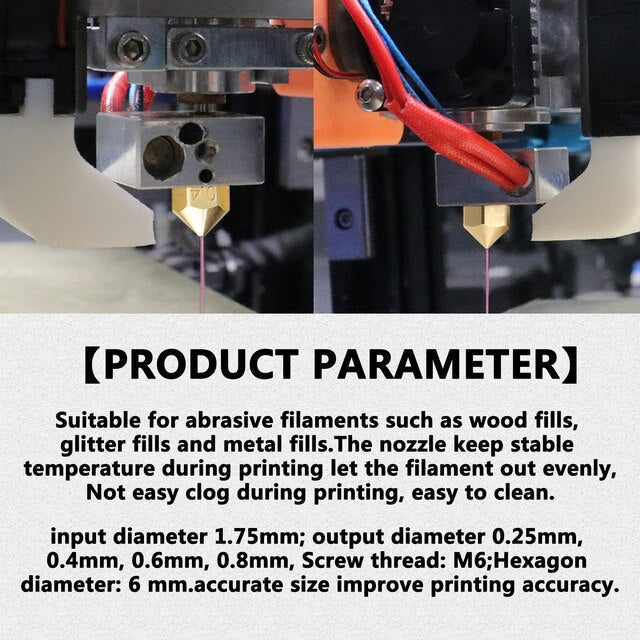

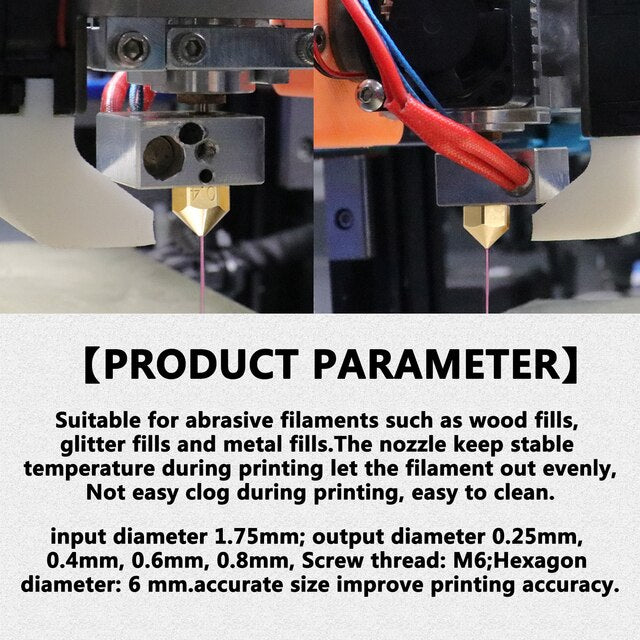

【PRODUCT PARAMETER】

Suitable for abrasive filaments such as wood fills, glitter fills and metal fills.The nozzle keep stable temperature during printing let the filament out evenly, Not easy clog during printing, easy to clean. input diameter 1.75mm; output diameter 0.25mm,

0.4mm, 0.6mm, 0.8mm, Screw thread: M6;Hexagon diameter: 6 mm.accurate size improve printing accuracy.

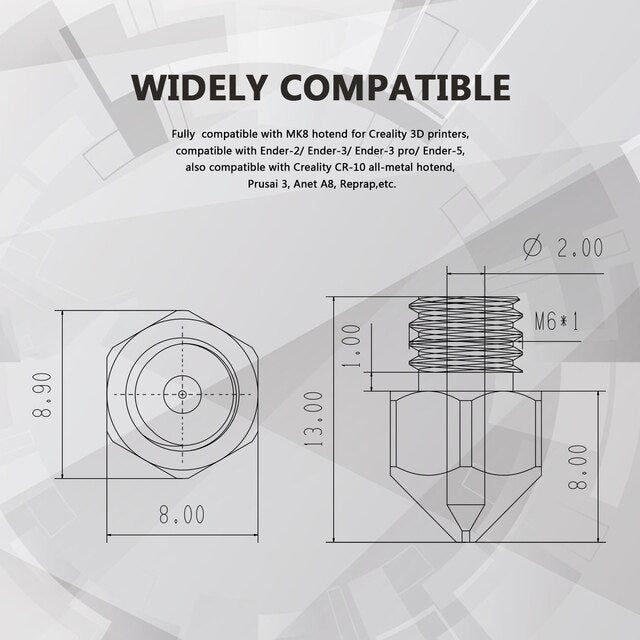

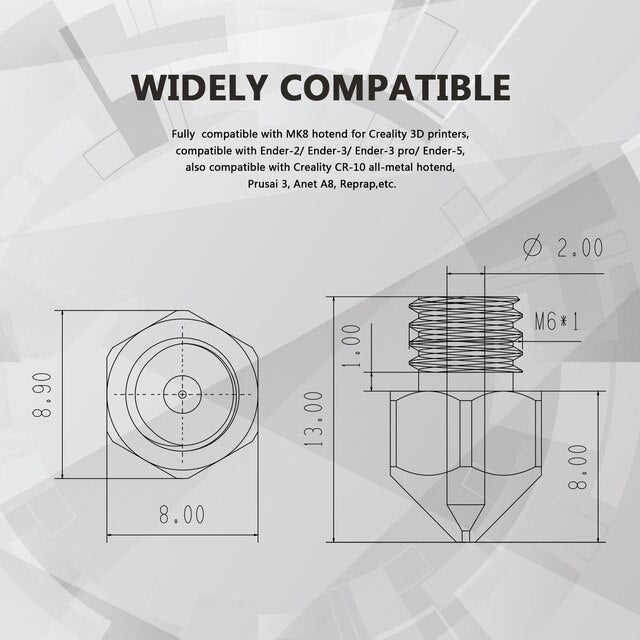

WIDELY COMPATIBLE

Fully compatible with MK8 hotend for Creality 3D printers, compatible with Ender-2/ Ender-3/ Ender-3 pro/ Ender-5, also compatible with reality CR-10 all-metal hotend,

Prusai 3, Anet A8, Reprap etc.

To replace the nozzle, follow these steps:

1. Turn on the 3D printer and preheat the hot end to approximately 220 to 250 degrees Celsius. The goal is twofold: melt any solidified material stuck inside the hot end and allow the metal to expand. Once the hot end reaches the desired temperature, use an adjustable wrench to hold onto the heater block.

2. Use either a socket wrench or a small wrench to turn the nozzle counterclockwise. Keep turning until the nozzle falls out. Exercise caution as the nozzle will be very hot.

3. When inserting the new nozzle, repeat the process while keeping it heated up. Use the adjustable wrench to hold the heater block and tighten the new nozzle. It's not recommended to tighten it by hand, as getting burnt by a hot nozzle can be painful.

5. Ensure the nozzle is tightened securely but avoid over-torquing. Hand-tight is sufficient; excessive force can lead to breaking the nozzle inside the heater block or causing damage.

Follow these steps carefully, and your new nozzle will be ready for seamless 3D printing with improved capabilities.

| 3D Printer Nozzle Performance Comparison | |||||

|---|---|---|---|---|---|

| Type | Thermal Conductivity (W/m.k) |

Hardness (Mohs) |

Maximun Printing Temp |

Coefficent of Thermal Expansion (µm/m.℃) |

Applicable Materials |

| Brass Nozzle | 105 | 3.0 | 300 | 18.0 | PLA, ABS, TPU, PA, PETG, etc. |

| Stainless Steel Nozzle | 17 | 5.0 | 350 | 6.0 | Food, Pills, etc. |

| Copper Plated Nozzle | 330 | 6.0 | 500 | 16.7 | PEEK, PEL, Carbon Fiber, Fiberglass, Wood Fiber, Metal Fiber, etc. |

| Hardened Steel

Nozzle (Blackened / Nickel Plated) |

22 | 7.8 | 450 | 8.0 | |

| Hardened Stainless Steel Nozzle | 22 | 8.0 | 450 | 6.0 | |

| Ruby Nozzle | 18 | 9.0 | 550 | 5.3 | For All Materials |